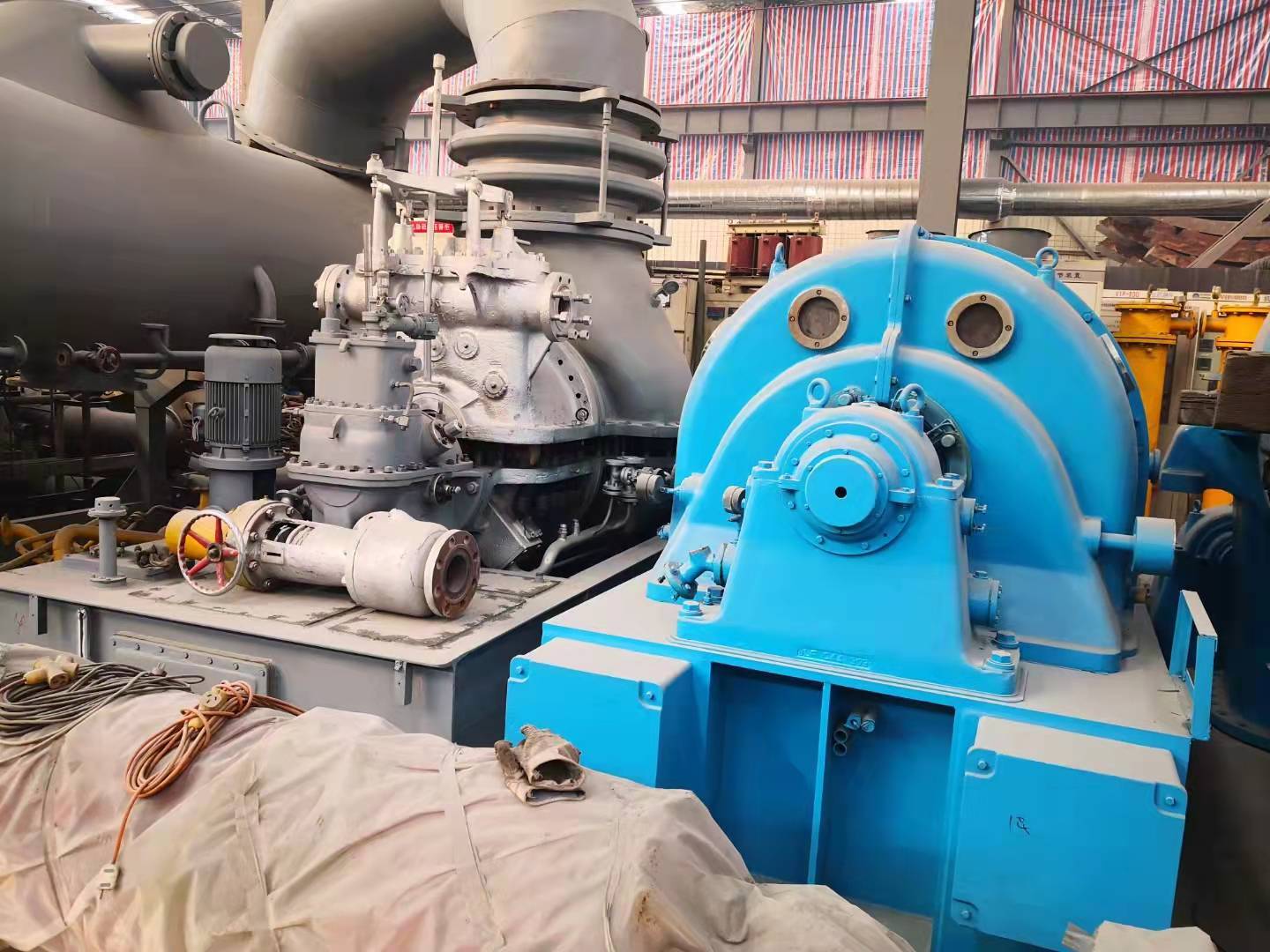

B12 Used Back Pressure Turbine

Price 1000000 USD ($)/ Unit

B12 Used Back Pressure Turbine Specification

- Product Type

- Used Back Pressure Turbine

- Material

- Stainless Steel

- Height

- 1800 mm

- Output Voltage

- 400 V

- Rated Power

- 11 MW

- Control System

- Automatic

- Max. Power

- 12 MW

- Turbine Efficiency

- 89%

- Voltage

- 415 V

- Frequency (MHz)

- 50 Hz

- Size

- 2400 x 1050 x 1800 mm

- Weight

- 6200 kg

- Color

- Grey

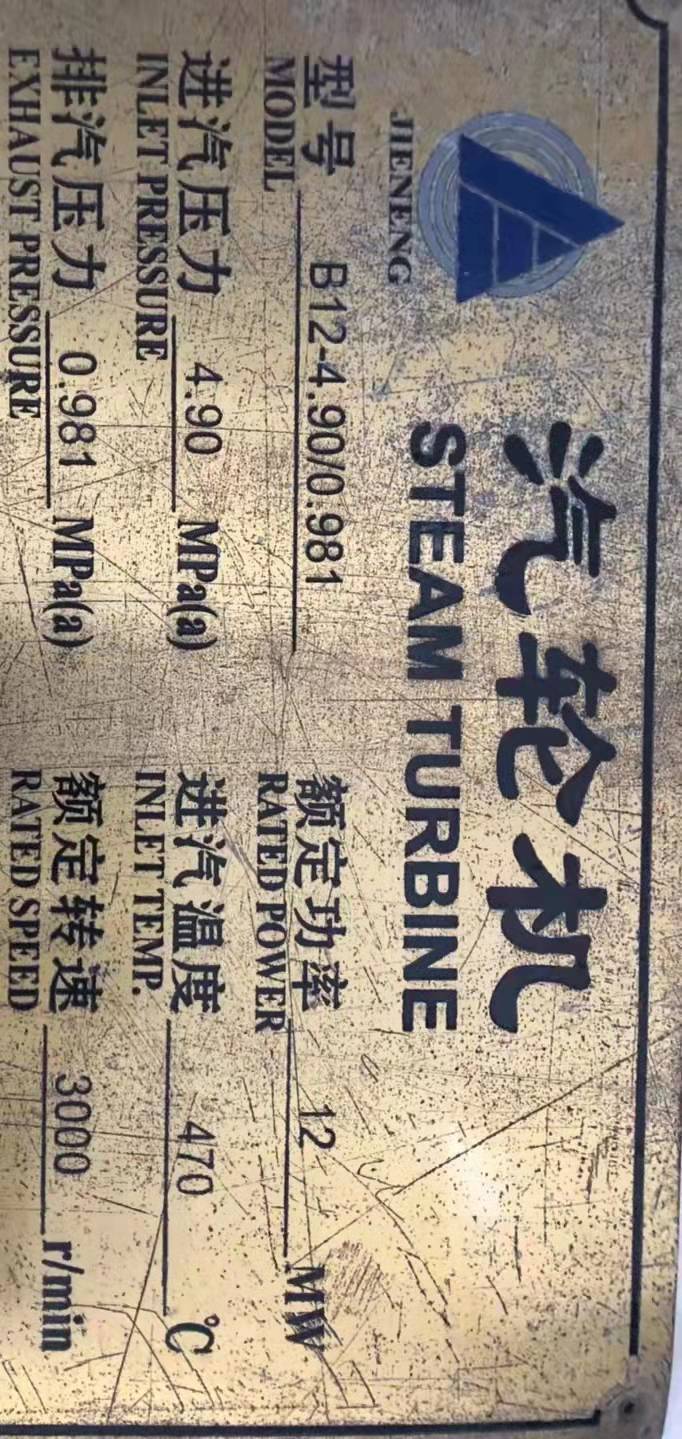

About B12 Used Back Pressure Turbine

Turbine model: B12-35/10

Generator model: QF-3-2

Rated power (kw):12000

Rated power (kw):12000

Rated speed (R / min):3000

Voltage (V):10500

Inlet steam pressure (MPA):3.43

Current (a):825

Inlet steam temperature :435

Speed (R / min):3000

Rated steam inlet (T / h):198

Frequency (Hz):50

Exhaust pressure (MPA):0.98

Power factor:0.8

Manufacturer:Shanghai steam turbine works

Insulation class:Class B

Year of manufacture: 85 year

Excitation mode:Coaxial excitation

Unit status: Very Good

Powerful and Efficient Energy Solution

This back pressure turbine stands out with its impressive 12 MW maximum power output and 89% efficiency, making it suitable for demanding industrial applications. Its automatic control system ensures smooth operation and optimal performance. Built from robust stainless steel, the turbine promises longevity and stable energy production. Minimal noise output makes it ideal for factory environments concerned with safety and comfort.

Compact Design with Advanced Controls

Despite its high output, the B12 turbine is engineered to be space-efficient, measuring 2400 x 1050 x 1800 mm. The advanced automatic control system streamlines operations and minimizes manual intervention, reducing maintenance and downtime. The output voltage range (400-415 V at 50 Hz) ensures compatibility with various installations, meeting diverse industrial requirements.

FAQ's of B12 Used Back Pressure Turbine:

Q: How does the B12 Used Back Pressure Turbine benefit industrial power generation?

A: The turbine offers high energy efficiency (89%) and a robust power output of up to 12 MW, making it ideal for industries requiring reliable on-site electricity generation. Its back pressure operation also allows for process steam extraction, supporting cogeneration and improving overall plant efficiency.Q: What are the usage applications for this back pressure turbine?

A: This turbine is suitable for industries like chemical manufacturing, food processing, and power plants. It can be integrated into systems where both electricity and steam are needed, supporting combined heat and power (CHP) operations for enhanced resource utilization.Q: When should I consider choosing a back pressure steam turbine over other types?

A: A back pressure turbine is advisable when your facility requires both electrical power and process steam simultaneously. This setup maximizes steam energy use, making it cost-effective and energy efficient for plants with continuous process steam demands.Q: Where is the B12 Used Back Pressure Turbine commonly installed?

A: It is most commonly found in industrial facilities across China and internationally, particularly where on-site power generation and steam utilities are integral to operations. Exporters, manufacturers, suppliers, and traders from China offer installation support and after-sales service.Q: What is the process for installing and commissioning this turbine?

A: Installation typically involves mounting the turbine on a suitable foundation, connecting steam, electrical, and automation systems, and conducting thorough safety checks. Commissioning follows with controlled startup, performance verification, and training on the automatic control system.Q: How does the automatic control system enhance turbine operation?

A: The automatic control system manages key operating parameters, ensuring safe and efficient performance. It reduces the need for constant manual intervention, improves response to load changes, and enhances overall operational reliability.Q: What are the key benefits of the turbine's stainless steel construction?

A: The use of stainless steel provides exceptional resistance to corrosion and wear, prolonging the turbine's life span. It also ensures structural integrity under high-pressure, high-temperature steam conditions, which is essential for long-term industrial use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pressure Recovery Turbine Category

PG6561B Gas Turbine Generator Set

Price 10000000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Voltage : 11000 V

Size : 10.8 m x 3.6 m x 4.2 m

Product Type : Gas Turbine Generator Set

Material : Highgrade Alloy Steel

Blast Furnace Top Gas Recovery Turbine Unit

Minimum Order Quantity : 1 Unit

Voltage : 11,000 V

Size : 12 m x 4 m x 7.5 m

Product Type : Blast Furnace Top Gas Recovery Turbine Unit

Material : Alloy Steel

TRT Used Top Pressure Recovery Turbine

Price 10000000 USD ($) / Unit

Minimum Order Quantity : 1 Container

Voltage : 220240 Volt (v)

Size : Standard

Product Type : Recovery Turbine

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese