Used Continuous Casting Equipment

Price 1000000 USD ($)/ Unit

MOQ : 1 Container

Used Continuous Casting Equipment Specification

- Casting Process

- Continuous Casting

- Usage & Applications

- Industrial metal casting and steel manufacturing

- Load Capacity

- Up to 100 Tons

- Product Type

- Used Continuous Casting Equipment

- Material

- Alloy Steel

- Surface Finishing

- Polished

- Weight

- Approx. 12000 Kg

- Color

- Metallic Grey

About Used Continuous Casting Equipment

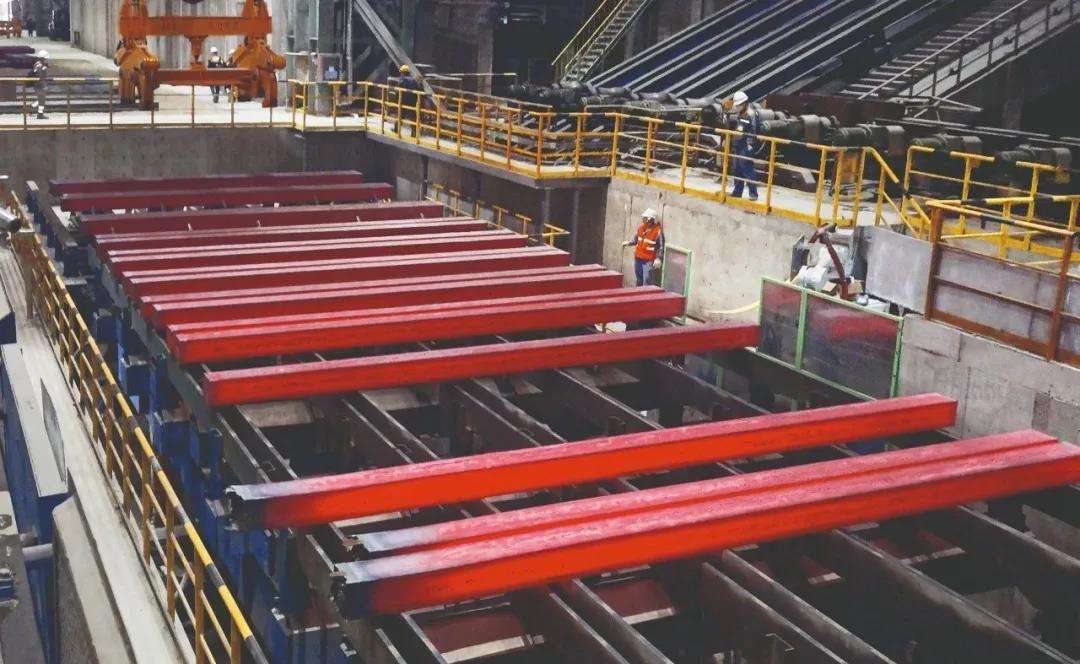

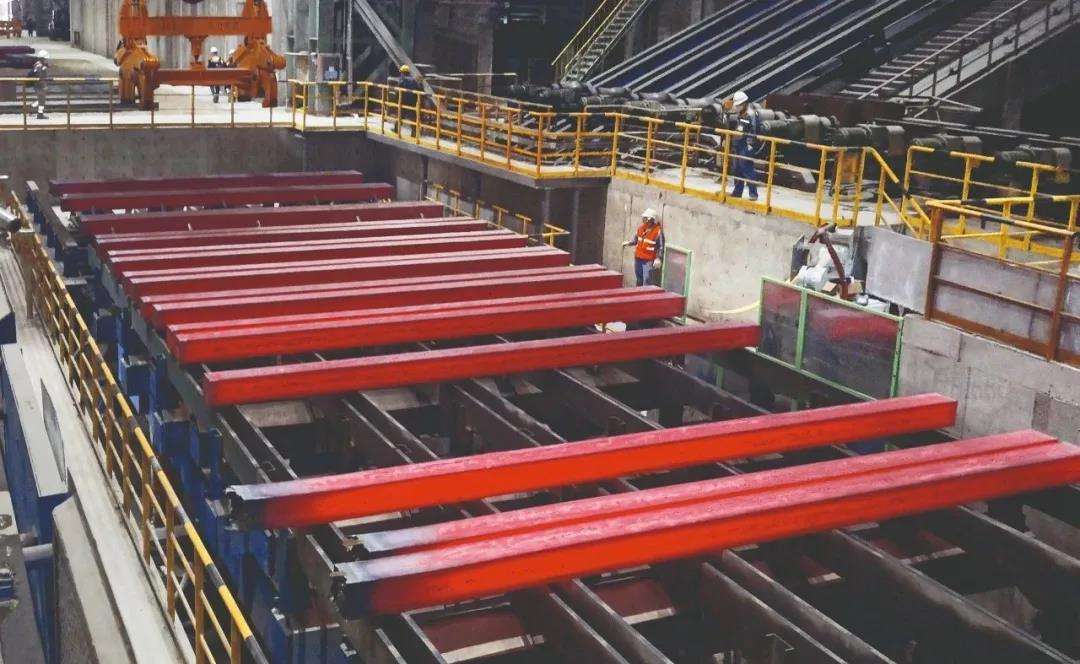

We can provide customers with all kinds of billet, bloom and slab continuous casting equipment.

Scope of supply: shaking table, crystallizer, tension leveler, flexible (hard) dummy bar traction, roller track, conveying track, steel pushing storage, Siemens frequency conversion electric control, pump station

Provide billet and slab continuous casting equipment.

6-meter arc, 8-meter arc, 9-meter arc, single machine single flow, double machine double flow, four machine four flow, five machine five flow and other models of second-hand continuous casting equipment.

Versatile Metal Casting Solutions

This equipment is designed to support the continuous casting process across a variety of metal types and alloys. With adaptable dimensions and strand numbers, manufacturers can optimize production runs for different material requirements. Its robust construction and polished finish ensure reliable, long-term operation in demanding industrial environments.

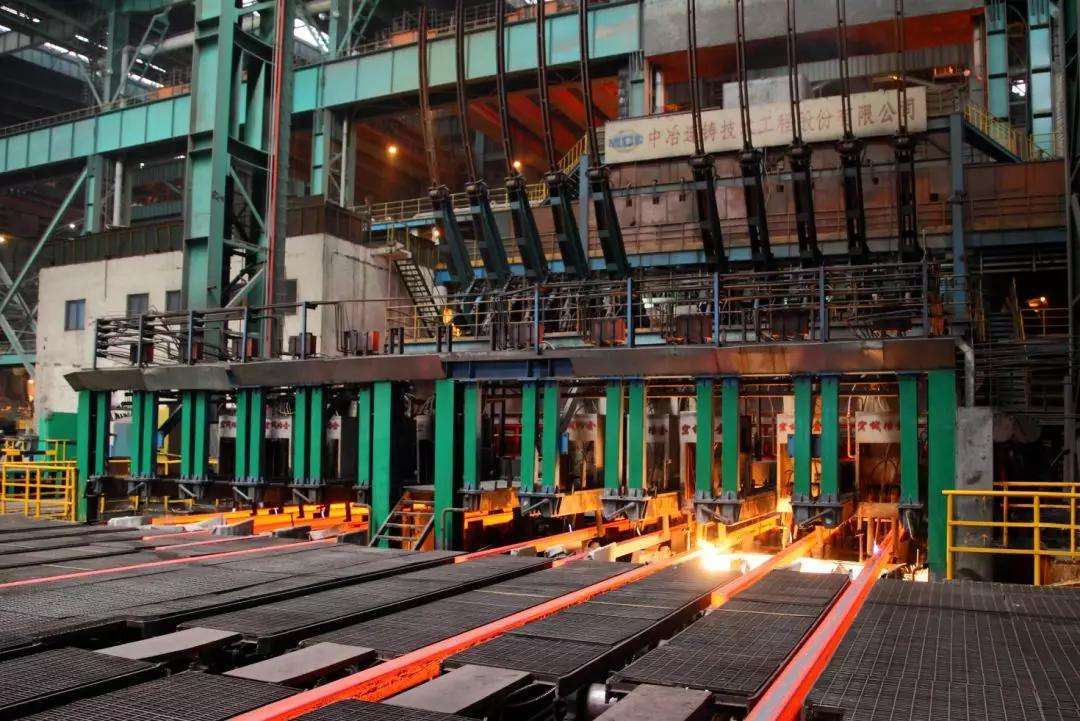

Optimized Performance with Efficient Cooling

Featuring a water-cooling system and copper alloy molds, the equipment maintains operational stability even at high temperatures up to 1500C. This ensures product quality and consistency throughout the casting cycle while preventing premature wear and maximizing production efficiency for steel mills and alloy foundries.

FAQ's of Used Continuous Casting Equipment:

Q: How does the semi-automatic operation benefit the continuous casting process?

A: The semi-automatic design streamlines routine operations, enhancing productivity while still granting operators manual control for adjusting parameters and responding to specific production needs. This ensures both efficiency and adaptability for a range of metal casting requirements.Q: What types of metals can be cast with this equipment?

A: This machine is suitable for industrial casting of steel, copper, aluminum alloys, ductile iron, and alloy steel, making it versatile for manufacturers dealing with various metal products.Q: When is it advisable to perform maintenance on the casting equipment?

A: Regular maintenance should be scheduled based on usage levels, operational hours, and observed wear. Since service life depends on prior maintenance and use, adhering to manufacturer and supplier recommendations ensures optimal performance and longevity.Q: Where is this casting equipment most commonly used?

A: This equipment is predominantly used in industrial metal casting facilities, steel manufacturing plants, and foundries requiring efficient, continuous production of billets and slabs.Q: What is the process flow when using this casting machine?

A: Molten metal is poured into copper alloy molds, cooled by water, and continuously cast into predetermined dimensions. The semi-automatic system manages critical parameters, enabling consistent output and quality control.Q: What are the key benefits of water cooling and copper alloy molds?

A: Water cooling maintains stable operating temperatures, preventing overheating and equipment stress. Copper alloy molds enable rapid uniform cooling, contributing to higher surface quality and reduced defect rates in finished castings.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese