B6 Used Back Pressure Turbine

Price 1000000 USD ($)/ Unit

B6 Used Back Pressure Turbine Specification

- Product Type

- Back Pressure Turbine

- Material

- Alloy Steel

- Height

- 2200 mm

- Output Voltage

- 400 V

- Rated Power

- 5000 kW

- Control System

- Automatic

- Max. Power

- 5000 kW

- Turbine Efficiency

- 80%

- Voltage

- 400 V

- Frequency (MHz)

- 50

- Size

- 3400 mm (L) x 1350 mm (W) x 2200 mm (H)

- Weight

- 7200 kg

- Color

- Grey

- Inlet Steam Temperature

- 380°C

- Mounting Type

- Horizontal

- Inlet Steam Pressure

- 14 bar

- Max Output

- 5000 kW

- Exhaust Steam Pressure

- 1.2 bar

- Lubrication System

- Forced Circulation

- Speed

- 6700 RPM

- Blade Material

- Stainless Steel

About B6 Used Back Pressure Turbine

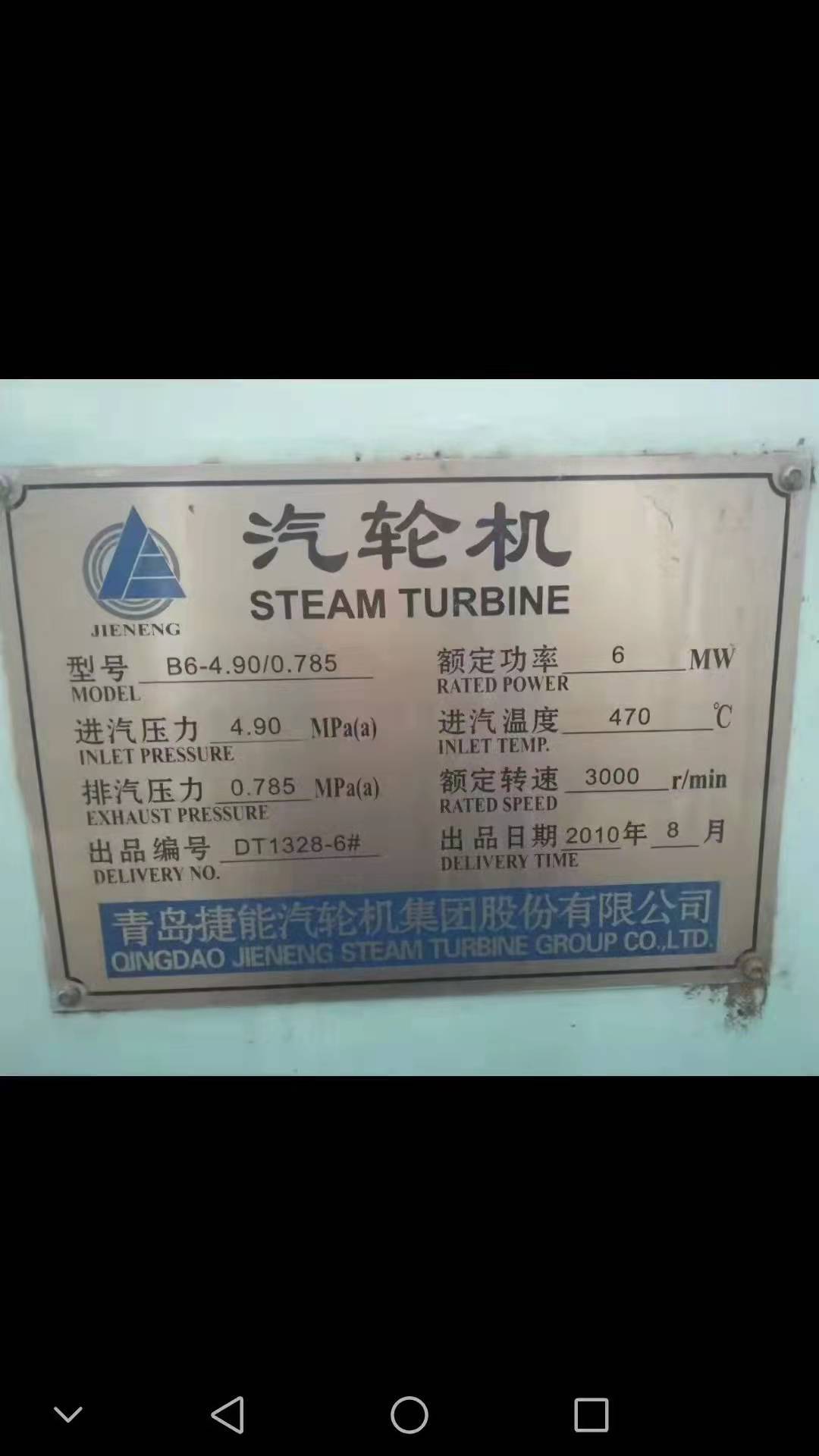

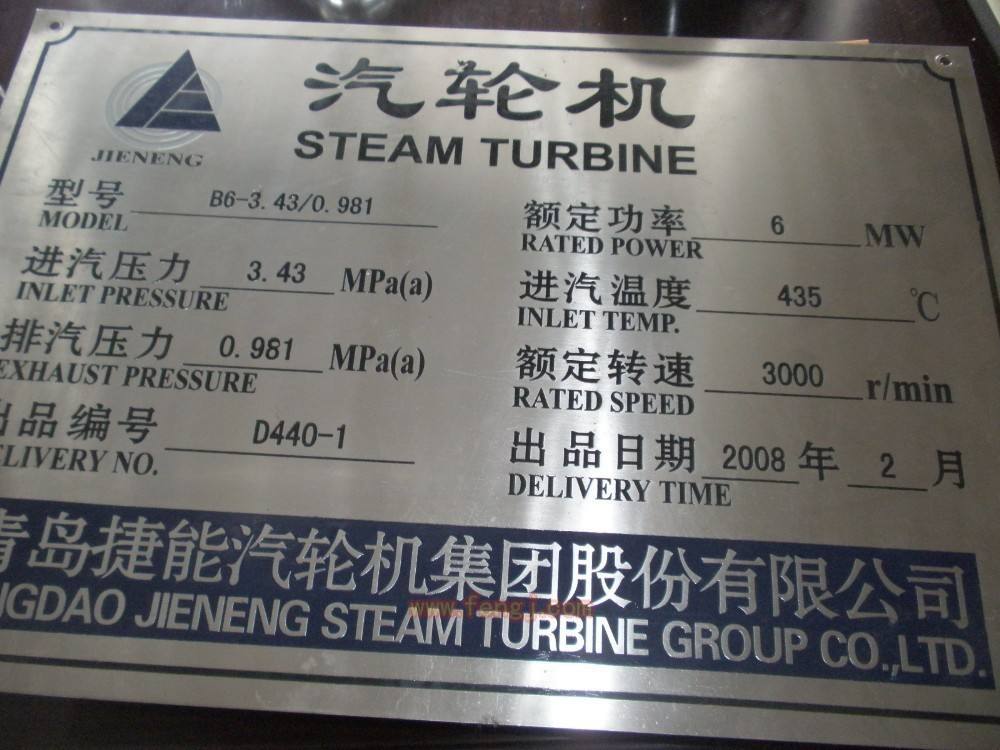

Model: c6-35 / 5

Rated power: 6000kW

Rated speed: 3000r / min

Steam inlet pressure: 3.43mpa (a)

Steam inlet temperature: 435

Exhaust pressure: 0.008mpa (a)

Extraction pressure: 0.49 MPa (a)

Exceptional Energy and Performance

Engineered for demanding industrial use, the B6 Used Back Pressure Turbine provides up to 5000 kW of power at a turbine efficiency of 80%. Its automatic control system ensures consistent performance while maintaining energy savings. The back pressure design allows for efficient combined heat and power applications, making it suitable for industries requiring both electricity and process steam.

Built to Last with Premium Materials

Manufactured from high-grade alloy and stainless steel, the turbine ensures remarkable durability and resistance to corrosion. Its forced circulation lubrication system and sturdy horizontal mounting enhance longevity and operational reliability, even under strenuous working conditions.

FAQ's of B6 Used Back Pressure Turbine:

Q: How is the B6 Used Back Pressure Turbine typically used in industrial settings?

A: This turbine is commonly used in combined heat and power (CHP) applications, where both electricity and low-pressure steam are required for industrial processes such as manufacturing, refineries, and chemical plants.Q: What benefits does the forced circulation lubrication system provide?

A: The forced circulation lubrication system ensures continuous and efficient oil flow to all moving parts, reducing wear and extending the lifespan of critical components, particularly at the high operating speeds of 6700 RPM.Q: When should I consider using a back pressure turbine instead of a condensing turbine?

A: You should opt for a back pressure turbine when the exhaust steam can be utilized for additional industrial processes, maximizing energy efficiency by producing both electricity and useful process steam.Q: Where are these turbines usually installed?

A: These turbines are most often installed in industrial facilities with a need for both electrical generation and process steam, such as paper mills, district heating plants, and processing industries.Q: What process does the turbine use to transform steam energy into electricity?

A: The turbine harnesses high-pressure, high-temperature steam (14 bar, 380C) to spin its stainless steel blades at 6700 RPM, driving a generator that converts mechanical energy into electricity output at 400 V and 50 Hz.Q: How does the automatic control system benefit operation?

A: The automatic control system simplifies operation, maintains optimal turbine parameters, and ensures safety by monitoring and adjusting variables in real-time, resulting in reliable and consistent performance.Q: What advantages does the stainless steel blade construction offer?

A: Stainless steel blades provide superior resistance to wear, corrosion, and high temperatures, which is essential for reliable, long-term performance under demanding process steam conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Steam Turbine Category

B15 Used Back Pressure Turbine

Price 1000000 USD ($) / Container

Minimum Order Quantity : 1 Container

Color : Blue

Size : Standard

Voltage : 220440 Volt (v)

Material : Stainless Steel

N6 Used Condensing Steam Turbine

Price 1000000 USD ($) / Container

Minimum Order Quantity : 1 Container

Color : Black

Size : Standard

Voltage : 220440 Volt (v)

Material : Metal

N3 Used Condensing Steam Turbine

Price 10000.0 USD ($) / Unit

Minimum Order Quantity : 1 Container

Color : Silver Grey

Size : 5100 mm x 1900 mm x 2250 mm

Voltage : 11000 V

Material : Alloy Steel

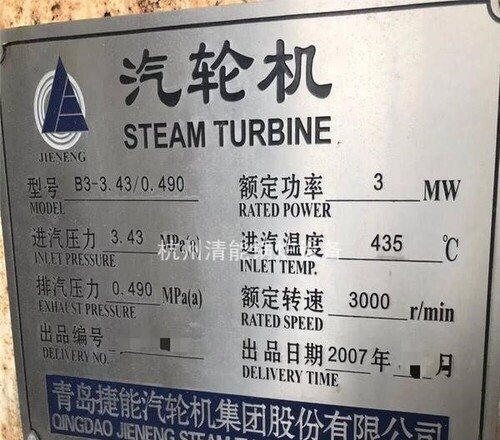

B3 Used Back Pressure Turbine

Price 1000000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Color : Grey

Size : Standard

Voltage : 400 V

Material : Mild Steel

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese