N30 Used Condensing Steam Turbine

Price 1000000 USD ($)/ Unit

N30 Used Condensing Steam Turbine Specification

- Product Type

- Used Condensing Steam Turbine

- Material

- High-Grade Alloy Steel

- Height

- 2200 mm

- Output Voltage

- 6300 V

- Rated Power

- 30 MW

- Control System

- PLC Automatic Control

- Max. Power

- 30 MW

- Turbine Efficiency

- ~37%

- Voltage

- 6300 V

- Frequency (MHz)

- 50

- Size

- 4200 mm x 2000 mm x 2200 mm

- Weight

- 32 Tons

- Color

- Industrial Grey

- Steam Inlet Pressure

- 3.43 MPa

- Steam Inlet Temperature

- 450°C

- Exhaust Pressure

- 0.005 MPa

- Application

- Power Plant, Industrial Steam Generation

- Max Outlet Capacity

- 30,000 kW

- Speed

- 3000 rpm

About N30 Used Condensing Steam Turbine

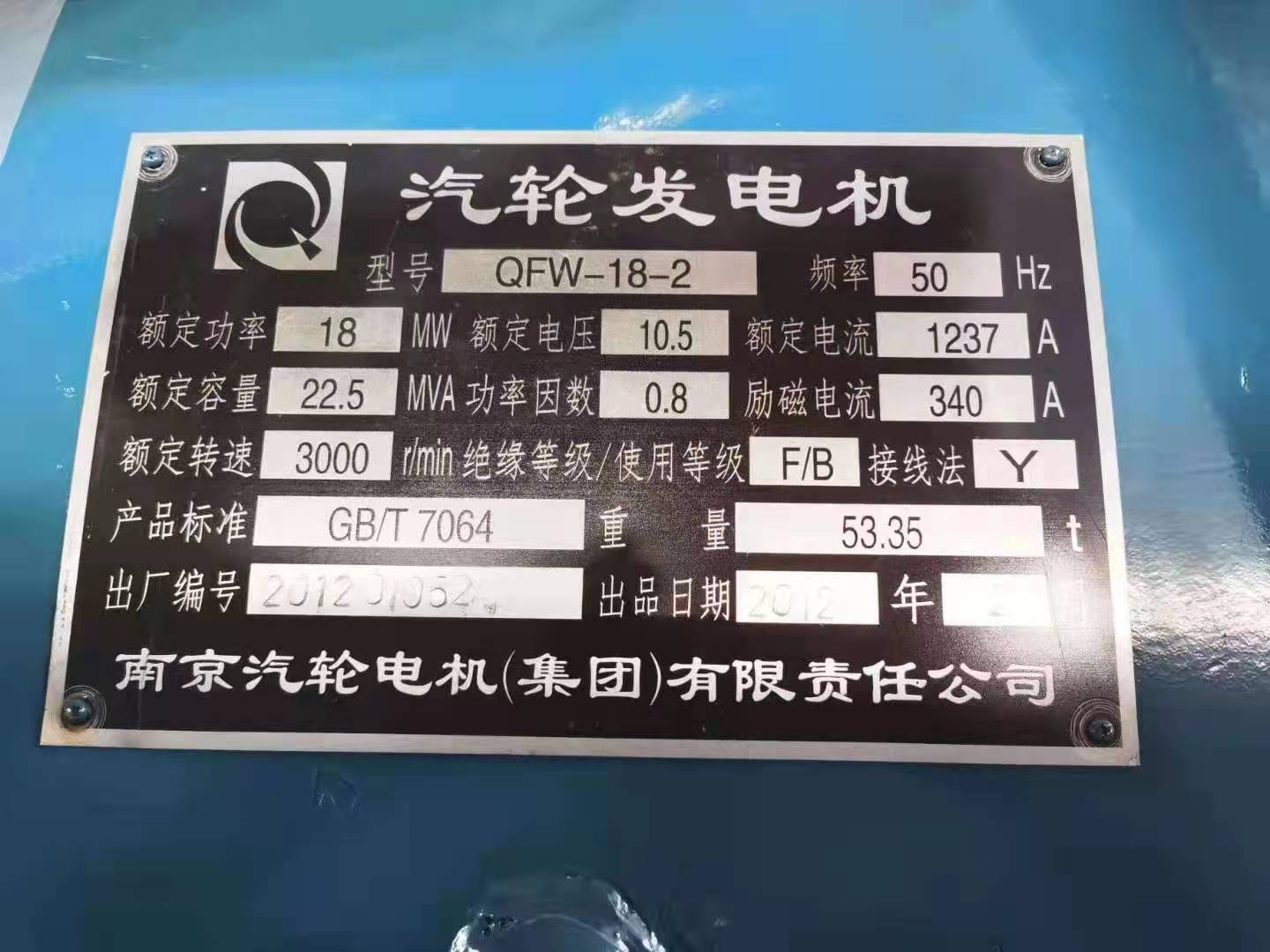

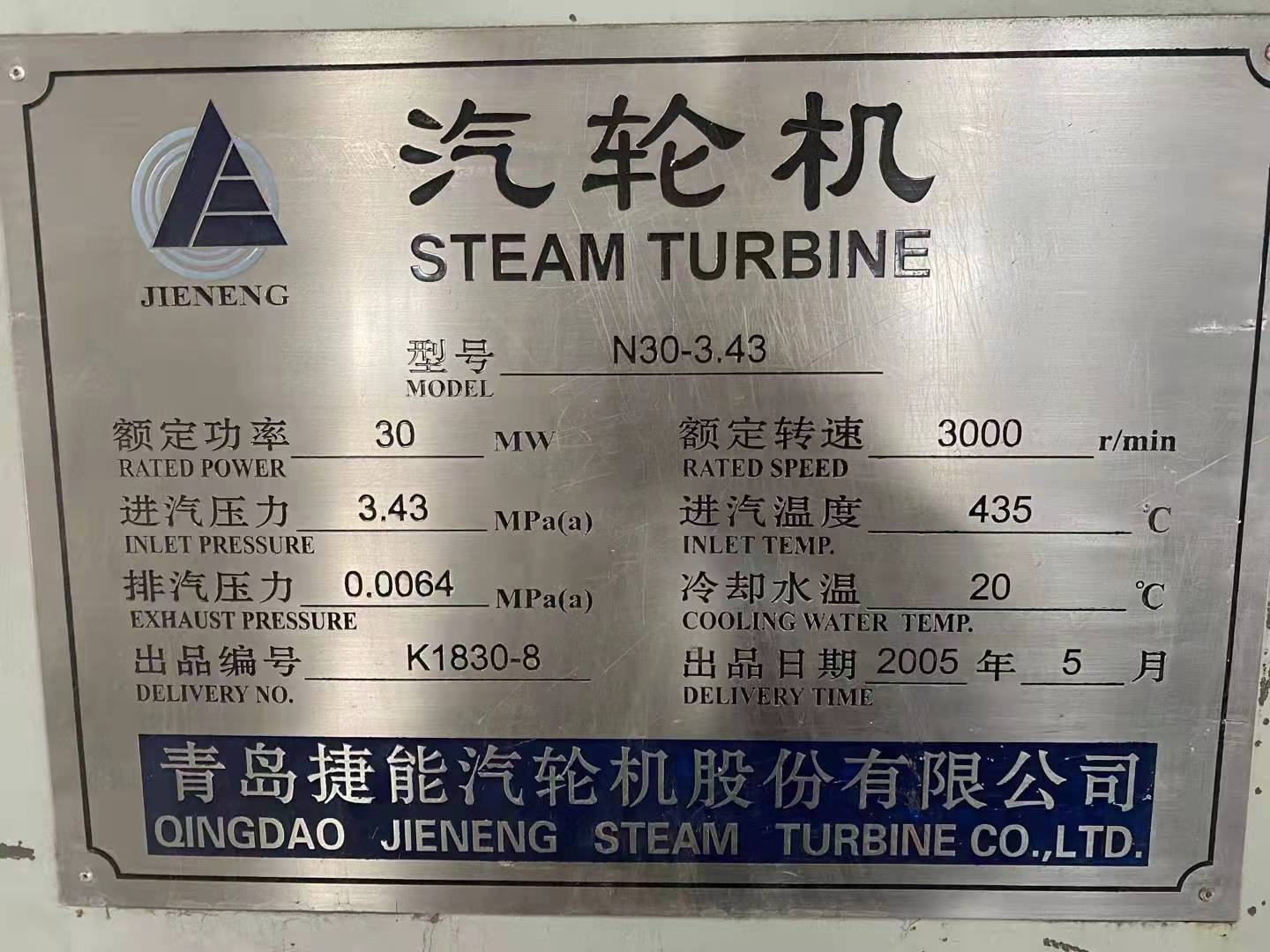

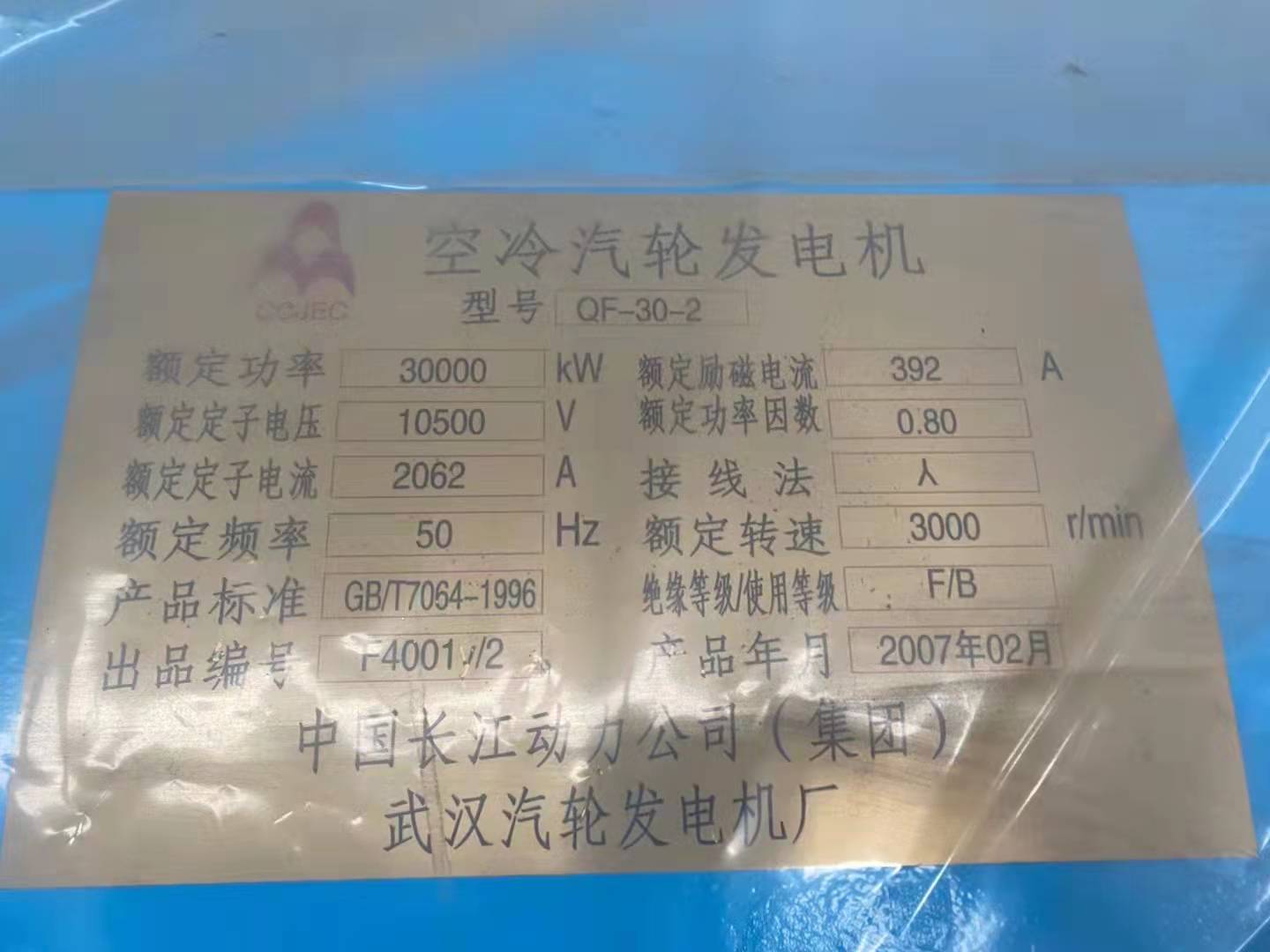

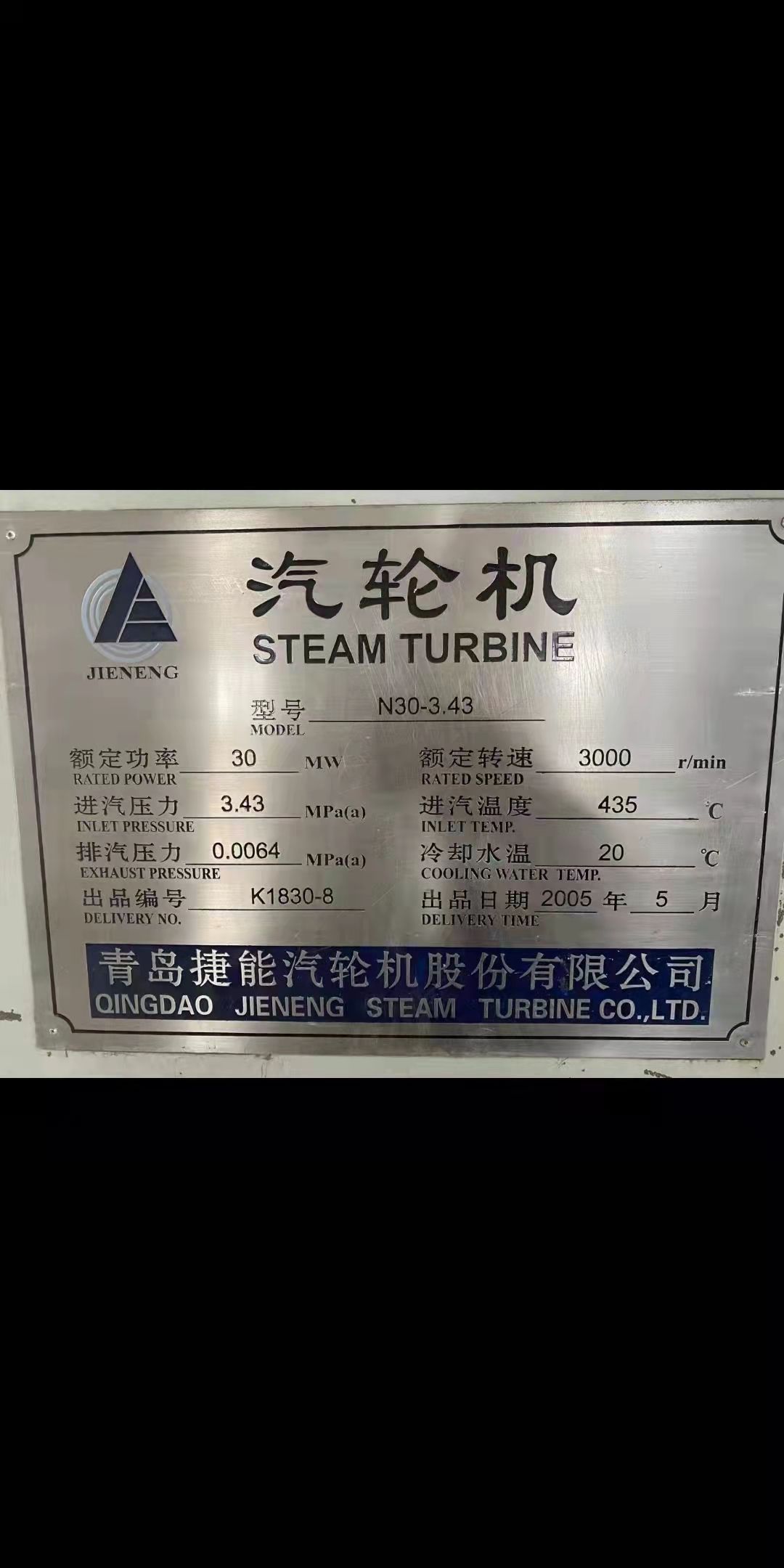

Model: n30-3.43

Rated power: 30mV

Rated speed: 3000r / min

Steam inlet pressure: 3.43mpa (a)

Steam inlet temperature: 435

Exhaust pressure: 0.0064mpa (a)

Cooling water temperature: 20

Advanced Performance Features

The N30 Used Condensing Steam Turbine features a cutting-edge design with a steam inlet pressure of 3.43 MPa and an inlet temperature of 450C, supporting high power generation and operational dependability. Its durable alloy steel construction and advanced control systems emphasize reliability and low maintenance, meeting the needs of demanding power plant conditions.

Versatile Industrial Applications

Designed for both power plants and industrial steam generation, the N30 turbine's robust capacity and efficient condensing technology make it ideal for large-scale operations. Its compatibility with modern control systems enables easy integration within existing industrial infrastructures, delivering consistent, high-voltage output across a variety of uses.

Operational Reliability and Efficiency

Equipped with a PLC automatic control system and an efficiency rating of approximately 37%, the N30 turbine offers precise control and energy optimization. Its low exhaust pressure (0.005 MPa) and high output capacity ensure low operational costs and reliable power supply, contributing to overall process efficiency and sustainability.

FAQ's of N30 Used Condensing Steam Turbine:

Q: How is the N30 Used Condensing Steam Turbine installed and commissioned in a power plant?

A: The N30 turbine is delivered in a modular format and installed on a reinforced foundation. Professional technicians align and secure the turbine, connect it to steam and electrical systems, and calibrate the PLC automatic control for optimal operation. Commissioning involves system checks and performance tests to ensure seamless integration.Q: What are the primary applications of this steam turbine?

A: The N30 steam turbine is mainly used in power plants for electricity generation and in industrial facilities requiring large-scale steam generation. Its robust design supports various energy-intensive processes across heavy industries.Q: When is preventive maintenance typically required for the N30 turbine?

A: It's recommended to perform routine inspections and basic maintenance every 3,000 to 6,000 running hours. Full preventive maintenance and component inspection should be scheduled annually to ensure consistent operation and extend equipment lifespan.Q: Where is the N30 turbine manufactured and exported from?

A: This turbine is manufactured in China and is available across global markets through authorized exporters, manufacturers, suppliers, and traders specializing in industrial equipment.Q: What process does the N30 turbine use for steam energy conversion?

A: The turbine operates on a condensing cycle, expanding high-pressure, high-temperature steam (3.43 MPa, 450C) through its stages to produce mechanical power. The spent steam is condensed at low exhaust pressures (0.005 MPa), maximizing energy extraction and efficiency.Q: How does the PLC automatic control system benefit turbine operation?

A: The PLC automatic control system enables precise monitoring and adjustment of turbine parameters, improving safety, operational stability, and efficiency. It facilitates quick fault detection and reduces manual intervention, supporting uninterrupted performance.Q: What are the key benefits of choosing the N30 Used Condensing Steam Turbine?

A: Key benefits include high energy efficiency (~37%), large power output (30 MW), durable construction, and compatibility with modern control systems. Its reliable operation supports reduced downtime and lower maintenance costs, delivering substantial value for industrial and power plant settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Steam Turbine Category

C6 Used Extraction Turbine

Price 1000000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Frequency (MHz) : 50 Hz

Product Type : Used Extraction Turbine

Size : Large

Color : Grey

B6 Used Back Pressure Turbine

Price 1000000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Frequency (MHz) : 50

Product Type : Back Pressure Turbine

Size : 3400 mm (L) x 1350 mm (W) x 2200 mm (H)

Color : Grey

N15 Used Condensing Steam Turbine

Price 1000000 USD ($) / Container

Minimum Order Quantity : 1 Container

Frequency (MHz) : 50 Hz

Product Type : Used Condensing Steam Turbine

Size : Approx. 5.5 m x 2.2 m x 2.8 m

Color : Grey

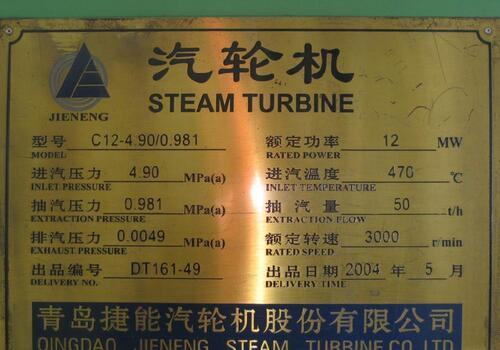

C12 Used Extraction Turbine

Price 100000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Frequency (MHz) : 50

Product Type : Used Extraction Turbine

Size : 3400 x 1800 x 2450 mm

Color : Metallic Grey

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese