Used Blast Furnace Centrifugal Fan

Price 1000000 USD ($)/ Unit

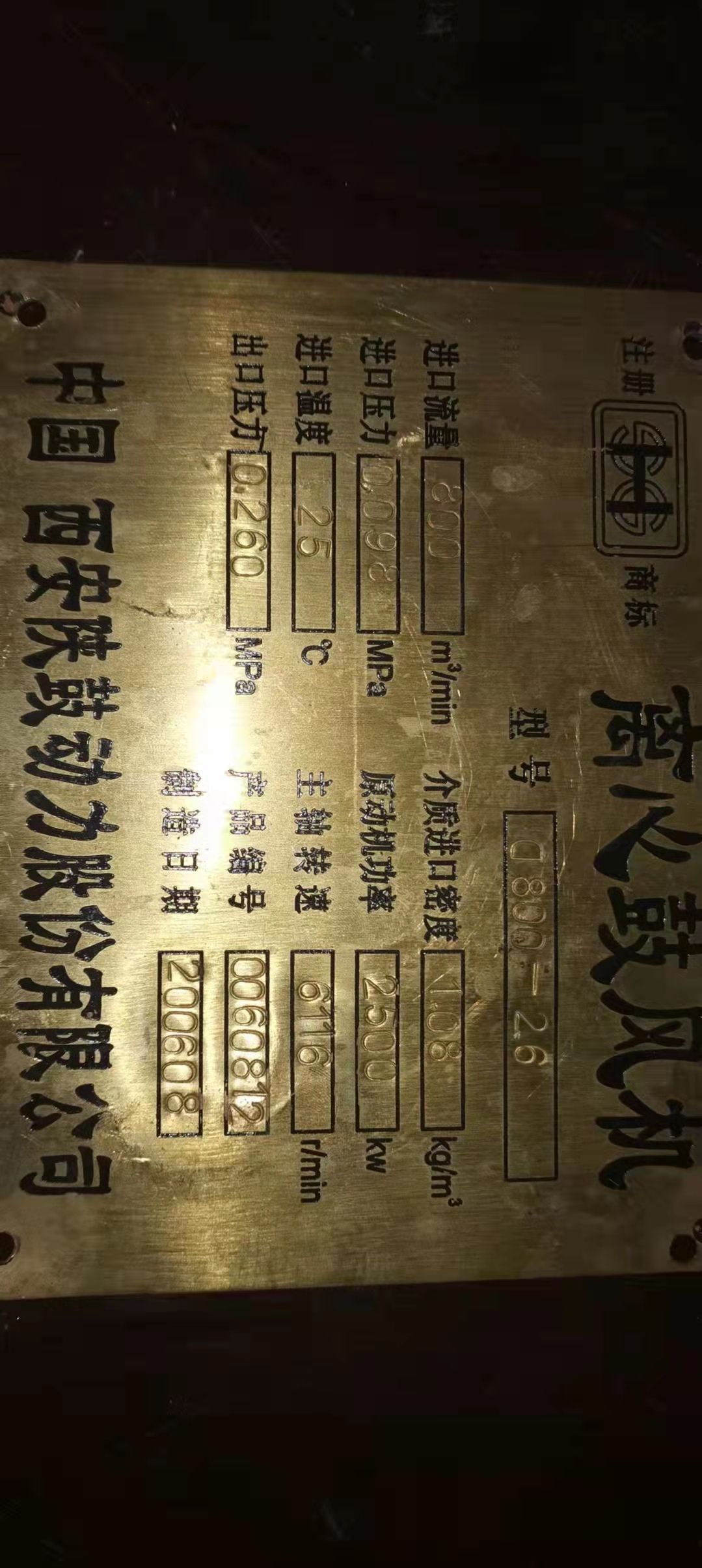

Used Blast Furnace Centrifugal Fan Specification

- Power Consumption

- 22 kW

- Revolution

- 1450/min

- Pressure

- 1320 Pa

- Voltage

- 380-440 V

- Noise Level

- 82 dB

- Speed

- 1450 RPM

- Power

- 30 HP

- Air Volume

- 9000-14000 m3/h

- Product Type

- Used Blast Furnace Centrifugal Fan

- Type of Fan

- Centrifugal Fan

- Power Mode

- Electric

- Installation Type

- Fixed

- Blade Material

- Mild Steel

- Shape

- Cylindrical

- Weight

- Approx. 850 kg

- Color

- Grey

- Drive Type

- Direct Coupling

- Inlet Diameter

- 700 mm

- Frequency

- 50 Hz

- Impeller Type

- Backward Curved

- Temperature Range

- Up to 250°C

- Condition

- Used

- Fan Housing Material

- Heavy Duty Steel

- Application

- Industrial, Metallurgical

- Outlet Diameter

- 600 mm

About Used Blast Furnace Centrifugal Fan

D Series blower is used to provide sufficient air for smelting blast furnace or Chemical industry, it is an important part of the blast furnace production.

This type blower inlet and outlet both are downward, the traditional two floors are used for the layout. The core unit of centrifugal blower, gear box and motor are arranged in the second floor, the control is located next to the machine train, which is easy to observe and operate. The lube oil station, valves, inlet & outlet valves are arranged in the first floor because of high discharge temperature, which need very good ventilation condition.

This type blower adopts the most advanced high efficient three-dimensional centrifugal blower Design and manufacturing technology. The integral machine train is featured by good quality and reliable condition and the efficiency is 8-10% higher than normal two-dimensional design.

The three space torsional blades, impeller disc and main shaft for the whole impeller of rotor is made up of high strength alloy steel, the impeller shall be made integral heat treatment and process quality conditioning after welding, which can guarantee the impeller whole crystal organization precision and also eliminate stress after welding, thus greatly increase the safety and reliability of impeller. Each impeller shall be done over-speed test with 15% working speed and the whole rotor shall be done with high precise dynamic balance test to guarantee stable and reliable operation.

Both the casing and diaphragm use resin sand casting, with higher density and bright appearance, each joint surface is sealed and reliable after precision machine and scraping.

Scope of supply:

|

Item |

Name |

Contains |

|

1 |

Fan |

Three-dimensional impeller rotor, casing, base frame, diaphragms and sealing, bearing and bearing base, coupling and protection hood, gas & oil port counter-flange, Coupling and shield for gearbox and fan, Coupling and shield for gearbox and motor, Diaphragm coupling, |

|

2 |

Oil Lubrication station |

Oil pump, cooler, Pressure gauge etc |

|

3 |

Overhead oil tank |

|

|

4 |

Gearbox |

Bearing and base frame, pairs of gear and bearing pad with hard gear surface. |

|

5 |

Whole Air valves and actuation mechanism |

Inlet electric control valve,Outlet baffle check valve,Outlet electric blow valve,Electric blow-off valve,Anti-surge valve |

|

6 |

Inlet & outlet compensator |

|

|

7 |

Anti-surge control and operation status monitoring system |

Primary and secondary instrument, anti-surge automatic control system, computer monitoring system, instrument panel, anti-surge electric control valve etc.. |

|

8 |

Self cleaning inlet air filter |

|

|

9 |

Blow-off silencer |

|

|

10 |

Motor |

6.6kv,11kv |

|

11 |

Control cabinet with soft starter |

High pressure run cabinet,star cabinet,soft starter,

Work station |

Robust Construction and Performance

Engineered for heavy industrial use, this centrifugal fan features durable heavy-duty steel housing and a backward curved mild steel impeller. Its direct coupling drive type ensures efficient power transfer, while the fixed installation design makes it reliable for continuous operation in high-temperature metallurgical settings up to 250C.

Industrial-Grade Airflow and Efficiency

Delivering an impressive air volume between 9,000-14,000 m3/h, the fan efficiently manages ventilation needs in blast furnaces and other industrial processes. The cylindrical shape, 700 mm inlet, and 600 mm outlet facilitate optimal airflow with a pressure capability of 1320 Pa and moderate noise output, supporting safe and productive work environments.

FAQ's of Used Blast Furnace Centrifugal Fan:

Q: How is the Used Blast Furnace Centrifugal Fan installed in an industrial setting?

A: The fan is designed for fixed installation, typically mounted securely on a designated base or platform within the facility. Professional installation is recommended to ensure proper alignment, electrical connections at 380-440 V, and secure placement for optimal performance and safety.Q: What applications are best suited for this centrifugal fan?

A: This fan is ideal for industrial and metallurgical applications, especially in blast furnaces or similar environments requiring high-temperature airflow management, reliable ventilation, and efficient particulate handling.Q: When should a facility consider using a backward curved impeller design?

A: A backward curved impeller is preferred when the application demands efficient energy consumption, stable airflow at high pressure, and low risk of dust accumulation or clogging-making it suitable for continuous-duty operations in harsh industrial settings.Q: Where can this used fan be sourced from?

A: The fan is supplied by leading exporters, manufacturers, suppliers, and traders based in China, offering global shipping options and comprehensive after-sales support to industrial clients.Q: What is the process for maintaining the fan to ensure longevity?

A: Routine maintenance involves regular inspections for wear, cleaning the impeller and housing, checking for vibrations or unusual noises, and ensuring all electrical and mechanical connections remain secure. Scheduled servicing helps maintain efficiency and extends operational life.Q: How does the fan's heavy-duty steel construction benefit industrial operations?

A: The robust steel housing enhances durability, supports continuous high-temperature operation up to 250C, and resists corrosion or deformation in demanding environments, thus reducing downtime and replacement costs over time.Q: What benefits does using a direct coupling drive type offer?

A: Direct coupling eliminates intermediate transmission components, reducing mechanical losses and maintenance needs. This results in better energy efficiency, lower operational noise, and more reliable performance for heavy-duty industrial air movement.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Furnace Fan Category

AV45 Used Axial Flow Fan Of Blast Furnace

Price 10000.0 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Power Mode : Electric

Air Volume : 1600021000 m/h

Power : 7.5 kW

Speed : 1450 RPM

AV50 Used Axial Flow Fan Of Blast Furnace

Price 10000000 USD ($) / Container

Minimum Order Quantity : 1 Unit

Power Mode : Electric

Air Volume : 32000 m/h

Power : 45 kW

Speed : 1450 RPM

AV40 Used Axial Flow Fan Of Blast Furnace

Price 10000000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Power Mode : Electric

Air Volume : 10000 m/h

Power : 3 kW

Speed : 1450 RPM

AV63 Used Axial Flow Fan Of Blast Furnace

Price 1000000 USD ($) / Unit

Minimum Order Quantity : 1 Container

Power Mode : Electric

Air Volume : 63000 m/h

Power : 55 kW

Speed : 960 RPM

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese