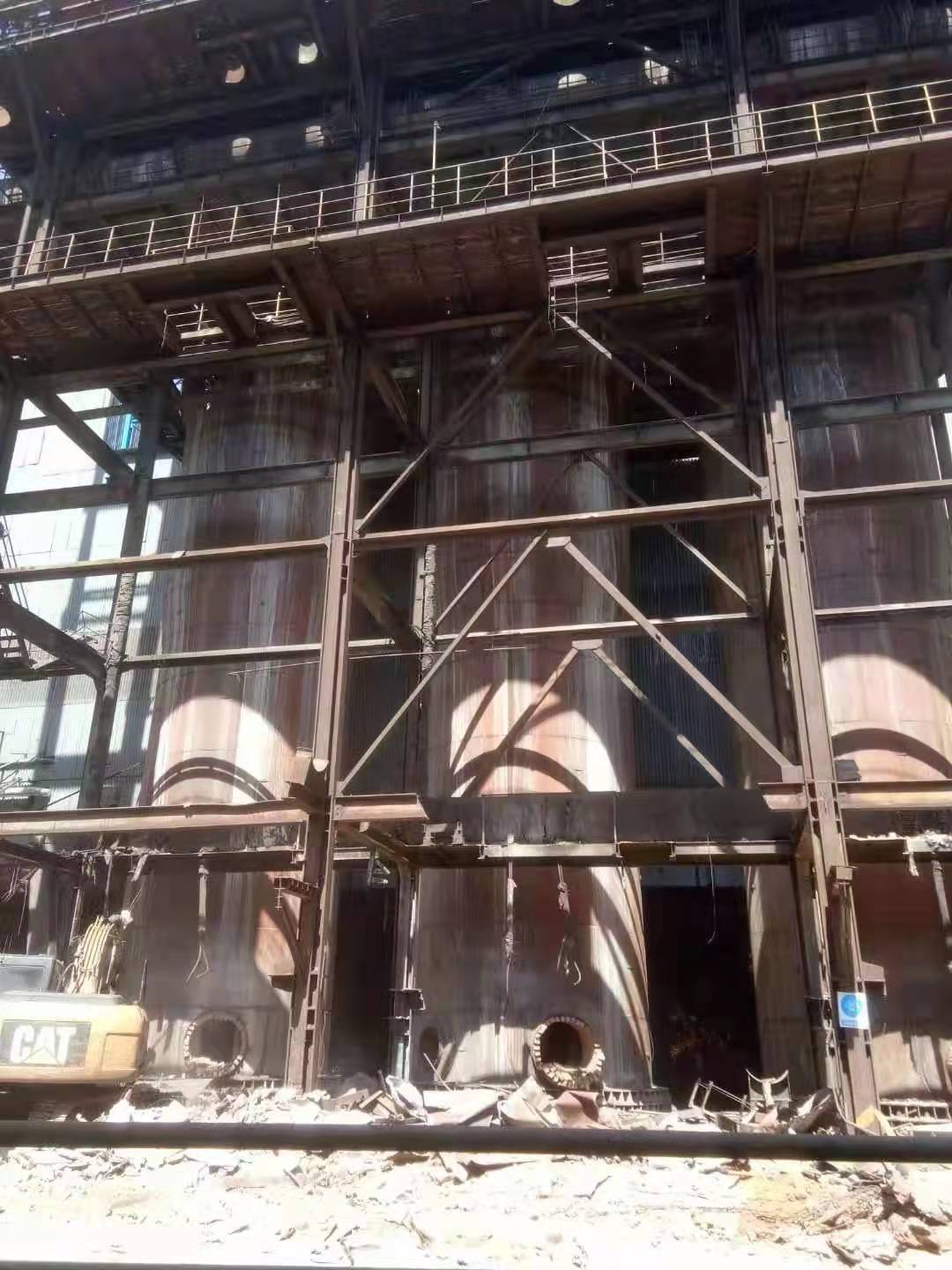

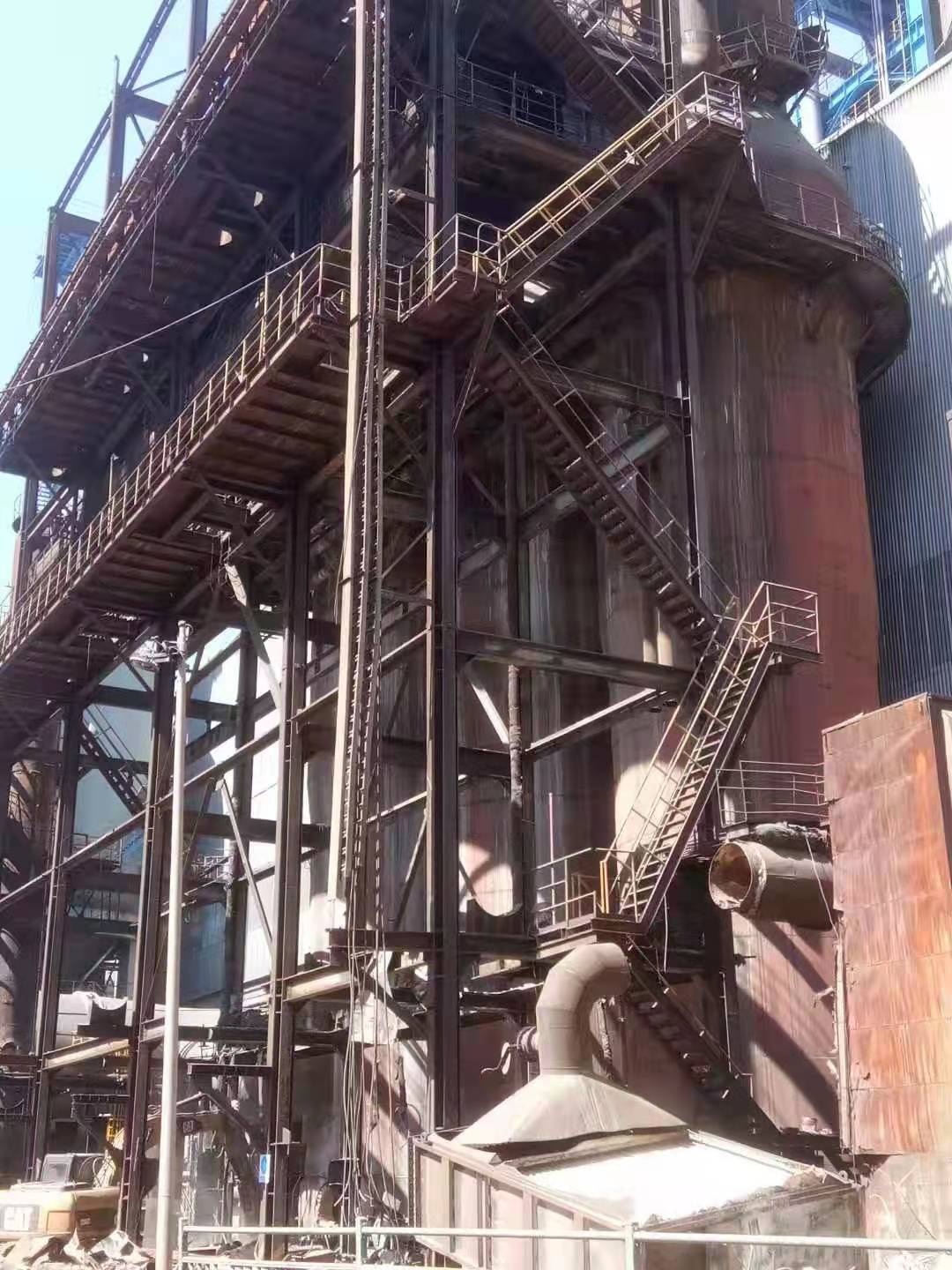

Used Blast Furnace

Price 10000000 USD ($)/ Unit

Used Blast Furnace Specification

- Rating

- Operational

- Feature

- Heavy-Duty Construction, Refractory Lining

- Condition

- Used

- Type

- Blast Furnace

- Usage

- Metallurgical Processing

- Power

- Electrical & Mechanical Power Sources

- Voltage

- 380V - 415V (Typical for Industrial Furnace)

- Size

- Industrial Scale

- Dimensions

- Varies; Approx. 12m x 8m x 25m

- Weight

- Approx. 40000 kg

- Application

- Iron and Steel Manufacturing

- Fuel Type

- Coke, Pulverized Coal

- Capacity

- Up to 2000 tons/day

- Output Material

- Hot Metal (Molten Iron), Slag

- Installation Service

- Available on demand

- Refractory Type

- High-alumina or magnesite bricks

- Cooling System

- Water-cooled panels

- Operation Mode

- Continuous

- Maintenance

- Periodic refractory lining maintenance recommended

- Corrosion Resistance

- Yes, due to special linings

- Automation Grade

- Semi-automatic / Manual

- Charger System

- Skip hoist or conveyor charger

- Year of Manufacture

- Varies; upon request

- Control System

- Legacy analog or upgradable to digital PLC

- Material of Construction

- Heavy-duty steel with refractory brick lining

About Used Blast Furnace

Scope of supply:

The main equipment includes: clay gun, opening machine and hydraulic equipment; Three kalukin hot blast stoves, equipped with combustion supporting air and double preheating system; Furnace top equipment and main winch; 8 distribution boxes, 1 large ash bin and 1 set of pneumatic ash conveying; Trough vibrating screen and conveyor belt; Crude gas system valve. The main equipment of public and auxiliary facilities includes: one set of BPRT fan av50-14 and AV45-12 units respectively; Lifting equipment: 3 sets of 125t crown block of cast iron machine, 2 sets of crown block in front of furnace and 3 sets of slag bailing crown block; One set of environmental protection dust removal in front of furnace, ore trough and cast iron machine; Several hot metal conveying vehicles and 65 t hot metal tanks; Double chain cast iron machine 60m * 3 sets; Clean circulating water system; One set of air compression and nitrogen production equipment; 2 gas release towers. PSA oxygen production 6250M / H) one set of equipment. 7500m / H) one set of equipment. One set of coal injection equipment (mill specification). One set of boiler gas power generation (specification).

Engineered for Heavy-Duty Metallurgical Processing

Constructed from premium steel and lined with high-quality refractory bricks (high-alumina or magnesite), this blast furnace withstands rigorous, continuous operations in demanding iron and steel production environments. Its lasting build and carefully designed water-cooled panels promote effective heat management and structural endurance.

Versatile Operation Modes and Advanced Controls

This furnace is available with semi-automatic or manual operation options. With legacy analog control systems, upgrades to advanced digital PLC controls are possible, providing flexibility for modernization and ease of integration into existing production workflows.

Reliable Capacity and Customizable Features

Industrial-sized dimensions and modular features allow capacities up to 2000 tons per day. Material charging can be managed by skip hoist or conveyor systems. The unit comes with various refractory lining options and is compatible with standard voltages (380V-415V). Installation and after-sales service are provided upon request.

FAQs of Used Blast Furnace:

Q: How is the used blast furnace installed and what support do you provide?

A: Installation services are available upon request, handled by experienced technicians. We provide guidance on site preparation, assembly, and commissioning to ensure optimal furnace performance and operational safety.Q: What are the main benefits of the heavy-duty construction and refractory lining?

A: The robust steel body and refractory brick lining (high-alumina or magnesite) offer excellent resistance to high temperatures and corrosion. This dramatically extends the operational life of the furnace and reduces downtime for repairs.Q: When should refractory lining maintenance be performed?

A: Periodic maintenance of the refractory brick lining is recommended based on operational intensity. Regular inspections and timely repairs help maintain optimal efficiency and prevent unplanned outages.Q: Where can this blast furnace be used most effectively?

A: This furnace is best suited for industrial applications in iron and steel manufacturing facilities, metallurgical plants, and foundries where continuous, high-capacity production is required.Q: What types of material and output does the furnace handle?

A: The furnace processes iron ore to produce hot metal (molten iron) and slag as the main outputs. It supports charging systems using a skip hoist or conveyor and is fueled by coke or pulverized coal.Q: How can the control system be adapted for modern use?

A: The standard legacy analog system can be upgraded to digital PLC control, allowing for enhanced automation, monitoring, and integration with modern plant management systems.Q: What makes the furnace resistant to corrosion?

A: Special corrosion-resistant linings protect the furnaces interior from chemical wear, significantly improving its durability, especially when operating under harsh process conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Blast Furnace Category

4500KVA Ferrosilicon Furnace

Price 10000000 USD ($) / Container

Minimum Order Quantity : 1 Container

Voltage : 3335 kV (Primary Voltage)

Size : Customized sizes available

Capacity : up to 25,000 TPA (as per plant design)

Rating : 4500KVA

8000KVA Submerged Furnace

Price 10000000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Voltage : 33 kV (input), Secondary as per design

Size : Customizable as per requirement

Capacity : 8 MVA (Megavolt Amperes)

Rating : 8000 KVA

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese