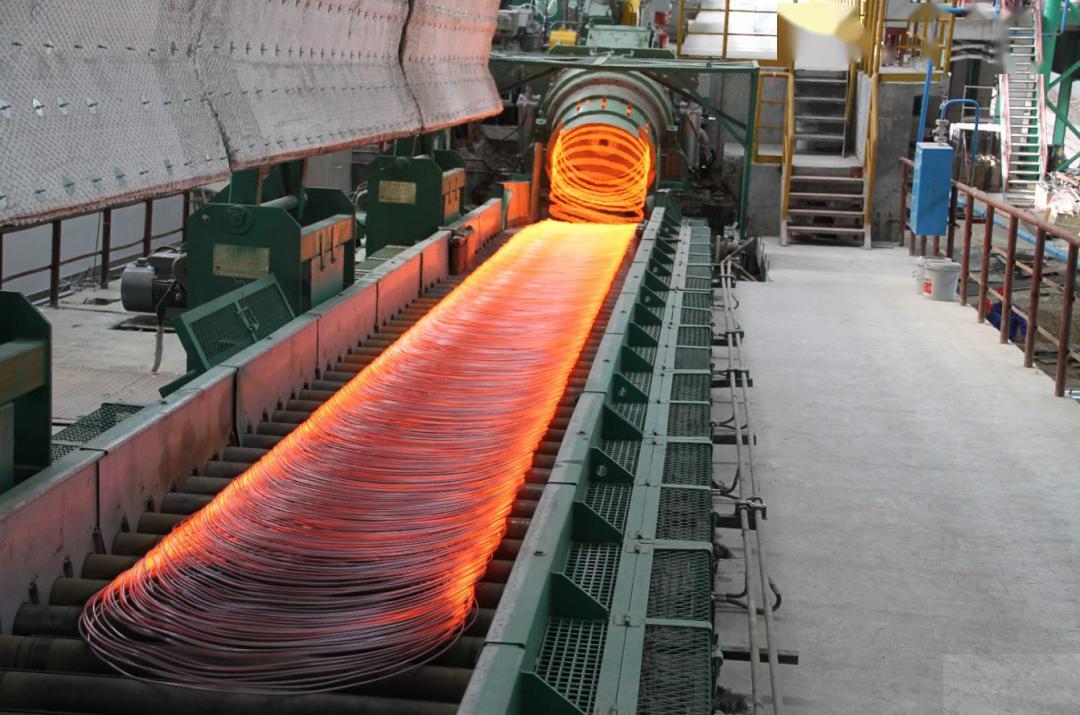

Used Wire Mill

Price 1000000 USD ($)/ Unit

Used Wire Mill Specification

- Type

- Wire Mill

- Material

- Mild Steel

- Capacity

- 10-20 Tons/Day

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Control System

- Manual

- Voltage

- 415 V

- Power

- 35 kW

- Weight

- Approx. 18 Tons

About Used Wire Mill

We can provide customers with complete second-hand wire rod production lines. These production lines have short service time and complete equipment, and can be removed at any time.

1. Billets: 150*150 continuous casting billet.

2. Finished product: section diameter: 5.5-20mm wire rod coil.

3. Annual capacity: five hundred thousand to ten hundred thousand tons/year

4. Steel type: low alloy steel, high quality carbon steel, alloy steel, spring steel etc..

5. Scope of supply dual-regenerative reheating furnace----- Roughing Mill------

1# Hot Cropping------1# Intermediate Mill--------2# Flying Shear-------2# Intermediate Mill--------Divide Into Two Line-------Pre-Finishing Mill------3# Flying Shear-------Finishing Block-------Tmt Device-------Laying Head------Air Cold Line------Coil Collection Station--------Pf Delivery Line------Press And Bundle-----Coil And Weigh

Versatile Wire Production Capabilities

The wire mill accommodates a broad product diameter range-1 mm to 12 mm-making it suitable for diverse wire rod applications. Its horizontal layout and efficient rolling process deliver accurate, consistent output, catering to various industry requirements.

Durable and Efficient Performance

Constructed from mild steel, this wire mill delivers robust durability whether in continuous production or heavy-duty drawing operations. With a semi-automatic manual control, it balances operational oversight with ease of use, making it reliable for everyday functioning.

FAQ's of Used Wire Mill:

Q: How is the used wire mill operated and controlled?

A: The wire mill uses a semi-automatic operation with a manual control system, allowing operators to finely adjust feed, speed, and processing parameters as required for different wire diameters and production requirements.Q: What processes can be performed using this wire mill?

A: This mill is suitable for wire rod production, drawing, and rolling, supporting a variety of applications where wire with a diameter range of 1 mm to 12 mm is required.Q: When is this wire mill most beneficial to use?

A: The mill is most advantageous in medium to large-scale manufacturing environments where flexibility, durability, and consistent output (between 10-20 tons/day) are essential but advanced computerization is unnecessary.Q: Where should the wire mill be installed for optimal performance?

A: To ensure safety and optimal productivity, install the mill in a spacious industrial setting with access to a 415 V power supply, proper ventilation, and material handling equipment. Please note, installation services are not provided.Q: What materials can be processed with this wire mill?

A: Primarily designed for processing mild steel, the mill delivers reliable performance for manufacturing sturdy wire rods and related products within its specified diameter range.Q: What are the main benefits of choosing this used wire mill?

A: Key benefits include cost-effectiveness, adaptability to diverse wire sizes, robust daily output, and operational simplicity through manual control-making it suitable for various exporters, suppliers, and traders.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rolling Mill Machine Category

750 Hot Strip Mill in Steel Plant

Price 1000000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Material : Alloy Steel

Automatic Grade : Automatic

Computerized : Yes

Type : Other, Hot Strip Rolling Mill

1450 Hot Roll Mill

Price 10000000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Material : Mild Steel

Automatic Grade : Automatic

Computerized : Yes

Type : Other, Hot Roll Mill

Used Bar Mill

Price 1000000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Material : Steel

Automatic Grade : Manual

Computerized : No

Type : Cold Rolling Mill

Cold Rolling Mill Machine

Minimum Order Quantity : 1 , , Unit

Material : Mild Steel

Automatic Grade : Automatic

Computerized : Yes

Type : Other, Cold Rolling Mill Machine

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese