10000 m3 Used Air Separation Equipment

Price 1000000000 USD ($)/ Unit

10000 m3 Used Air Separation Equipment Specification

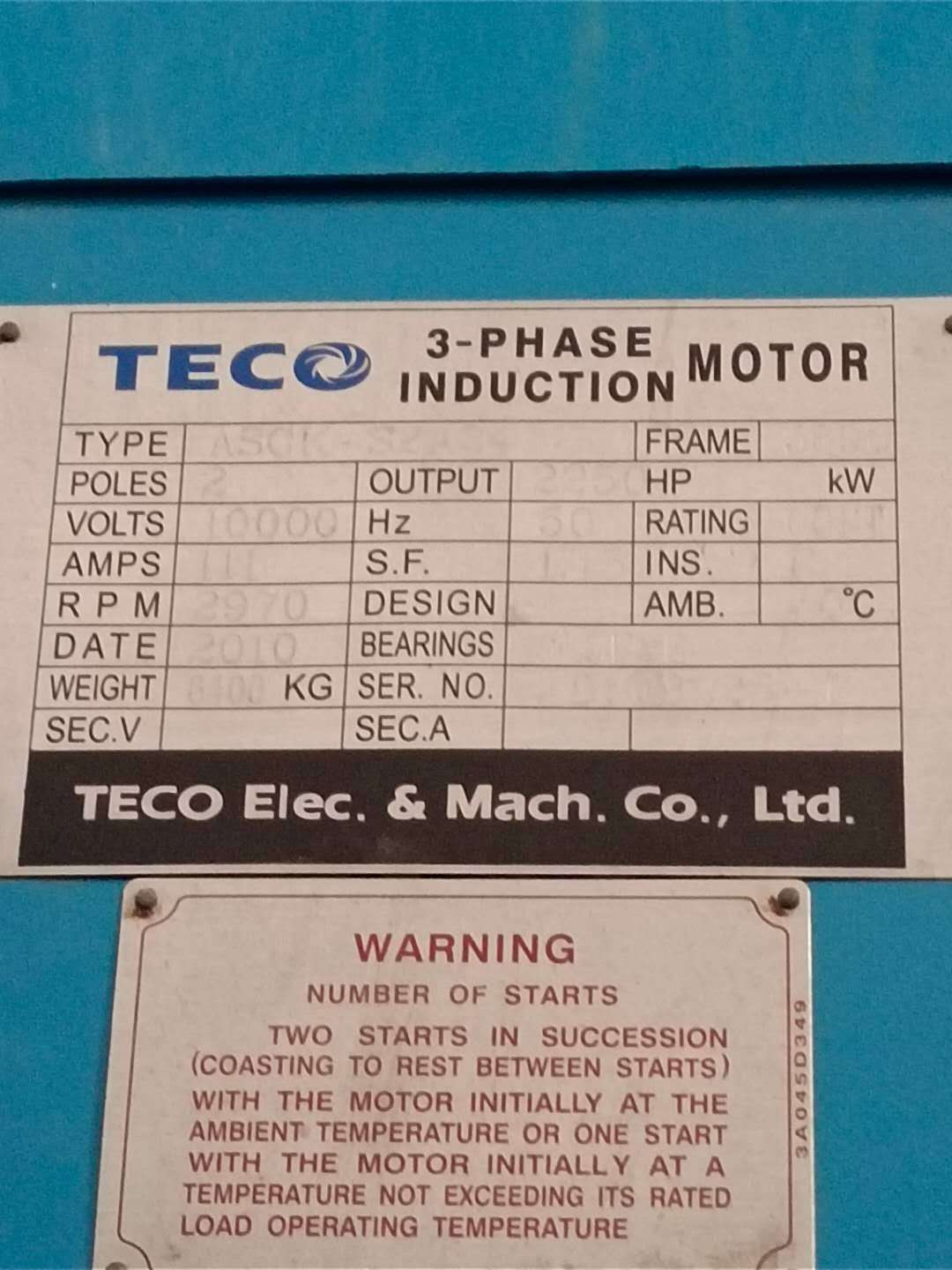

- Motor Power

- Custom per design (approx. 220 kW main drive)

- Speed

- Variable, based on demand and process control

- Model No

- ASE-10000

- Driven Type

- Electric Motor Drive

- Frequency

- 50 Hz

- Usage & Applications

- Industrial Gas Supply, Steel Plants, Chemical Industry, Hospitals, Petrochemical Plants

- Temperature Range

- -196C to +50C

- Efficiency (%)

- Up to 98%

- Automation Grade

- Fully Automatic

- Accessories

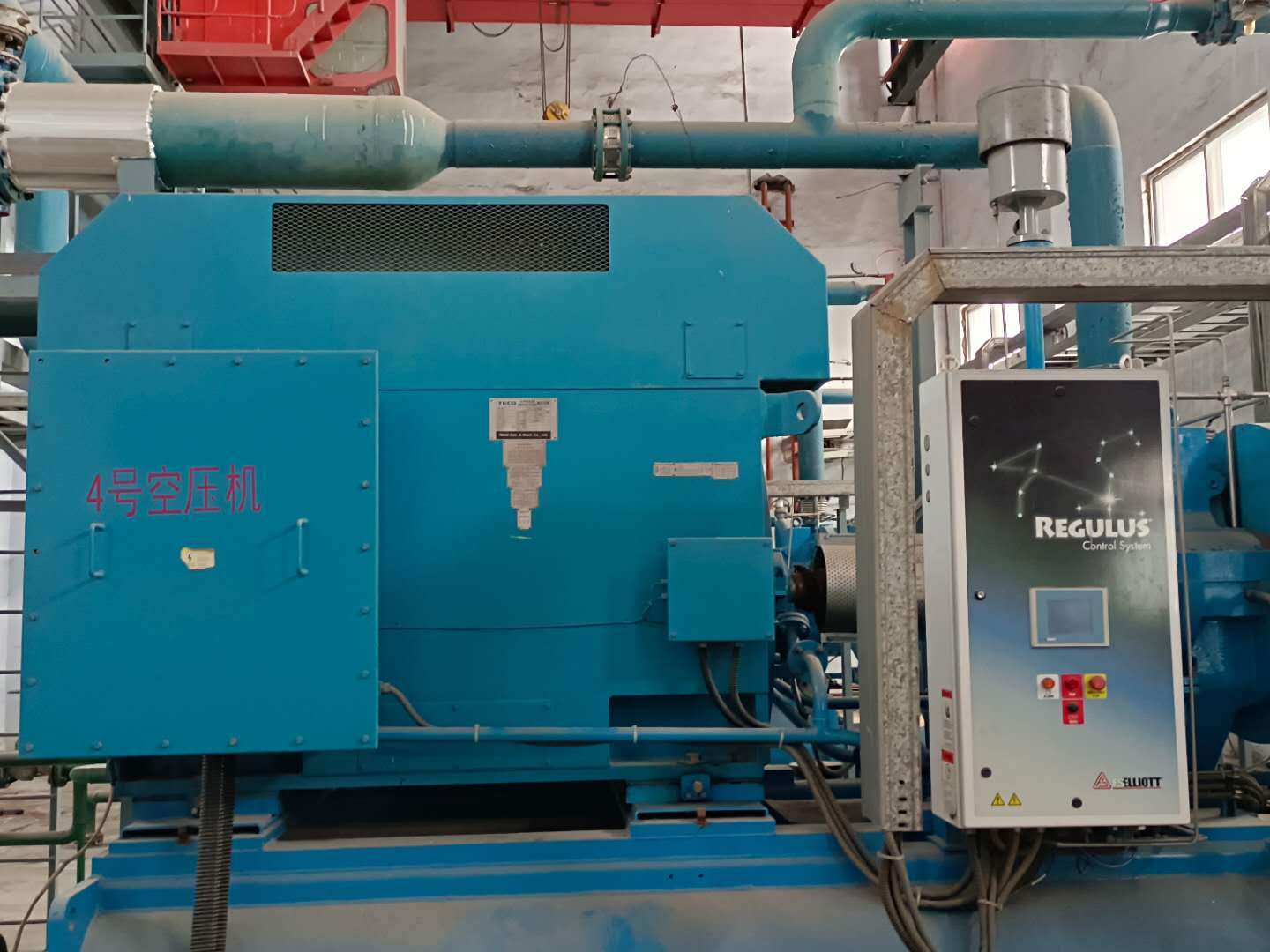

- Air Compressor, Expansion Engine, Purifier, Heat Exchanger, Control Panel, Instrumentation

- Installation Guideline

- Professional installation required, site foundation needed, adherence to safety & process standards

- Production Capacity

- 10000 m3 per hour

- Type

- Used Air Separation Equipment

- Material

- Stainless Steel

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Based Automatic Control

- Drive Type

- Electric

- Voltage

- 380V

- Power

- 220 kW

- Weight (kg)

- 65000 kg

- Dimension (L*W*H)

- Dependent on configuration; consult supplier

- Color

- Silver / Metallic

- Capacity

- 10000 m3/h

- Features

- High Purity Oxygen & Nitrogen Generation, Low Power Consumption, Robust Stainless Steel Structure, Skid-Mounted Design, Easy Maintenance Access, Efficient Heat Recovery System

- Machine Type

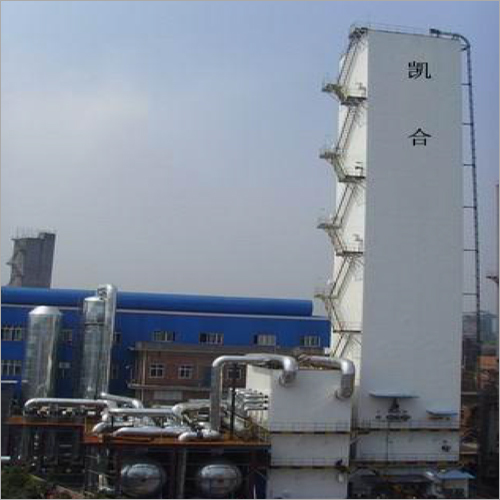

- Cryogenic Air Separation Plant

- Power Consumption

- Approximately 220 kW

- Surface Finish

- Polished / Anti-corrosive

About 10000 m3 Used Air Separation Equipment

Air products air separation unit Equipment parameters

| Product name | Output (nm)/h | purity | Outlet pressure |

| oxygen | 10000 | 99.6% | 15KPa |

| liquid oxygen | 200 | 99.6% | 80Kpa |

| nitrogen | 5000 | O23PPM | 8Kpa |

| liquid nitrogen | 50 | O23PPM | 200Kpa |

| Liquid argon | 330 | N23PPM | 80Kpa |

Scope of supply: complete set of equipment and technical data such as electric control system, instrument control system, air compressor, booster turbine expander system, fractionator system, molecular sieve purification system, air precooling system, etc.

High Purity Industrial Gas Generation

The ASE-10000 produces both oxygen (up to 99.7% purity) and nitrogen (up to 99.99% purity) through advanced cryogenic distillation. This enables diverse industrial uses, from large-scale steel manufacturing to chemical processes, where consistent, reliable gas quality is paramount.

Modular and Relocatable for Versatility

Designed with a modular, skid-mounted structure, the unit is easy to dismantle and relocate as production needs evolve. Whether expanding facility operations or setting up in a new location, this flexibility reduces installation time and associated costs.

Reliability and Safety as Standards

Engineered to operate for 15+ years with proper maintenance, the ASE-10000 incorporates robust safety systems, including automatic emergency shut-off, safety valves, and gas leak alarms. Extensive operational documentation and certifications accompany every unit, ensuring compliance and safe integration.

FAQ's of 10000 m3 Used Air Separation Equipment:

Q: How does the ASE-10000 air separation equipment achieve such high purity levels for oxygen and nitrogen?

A: The system utilizes cryogenic distillation, an advanced process that cools compressed air to extremely low temperatures, effectively separating oxygen and nitrogen at very high purity levels-up to 99.7% for oxygen and 99.99% for nitrogen. This method ensures reliable performance for critical industrial applications.Q: What documentation and certifications are provided with the used ASE-10000 plant?

A: Each refurbished ASE-10000 unit comes with an operation manual, detailed service records, and compliance certifications. These documents verify the equipment's reliability, refurbishment status, and adherence to international safety and quality standards.Q: Where can the ASE-10000 be installed, and what are the site requirements?

A: The ASE-10000 is suitable for a variety of industrial environments such as steel plants, chemical facilities, hospitals, and petrochemical sites. Installation requires a suitable site foundation, professional setup, and adherence to safety protocols as outlined in the operation manual.Q: What is included in the equipment package, and are storage options available?

A: The package includes the main cryogenic separation unit along with essential accessories like air compressor, expansion engine, purifier, heat exchanger, control panel, and instrumentation. Integrated liquid oxygen and nitrogen storage tanks are also available to streamline site operations.Q: How does the modular design benefit relocation or expansion?

A: The modular, skid-mounted design allows the ASE-10000 to be dismantled and relocated with relative ease. This flexibility is ideal for industries that anticipate changing production needs or need to move equipment between sites without significant downtime.Q: What services do you provide after purchase?

A: We offer on-site installation, operator training, commissioning, and comprehensive after-sales support. Additionally, export packaging is provided for international shipping, ensuring your equipment arrives safely and ready for immediate integration.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Air Separation Plant Category

500 Cubic Meters Liquid Air Separation Equipment

Minimum Order Quantity : 1 Unit

Color : Blue / Silver

Computerized : Yes

Voltage : 380440 V

Drive Type : Electric

Material : Stainless Steel

750 Cubic Meter Air Separation Plant

Minimum Order Quantity : 1 , , Plant

Color : Customizable

Computerized : Yes

Voltage : 380480 V Volt (v)

Drive Type : Electric

Material : Stainless Steel and Aluminum

550 Cubic Meter Air Separation Plant

Color : White

Computerized : Yes

Voltage : 380440V

Drive Type : Electric

Material : Heat Resistant and Durable Materials

3000 Cubic Meter Air Separation Plant

Color : White

Computerized : Yes

Voltage : 220440V

Drive Type : Electric

Material : Highgrade steel and specialized alloys

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese