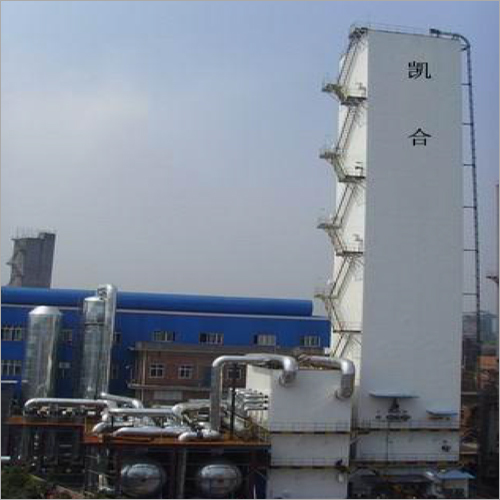

500 Cubic Meters Liquid Air Separation Equipment

500 Cubic Meters Liquid Air Separation Equipment Specification

- Frequency

- 50/60 Hz

- Temperature Range

- -196C to +50C

- Model No

- LAS500

- Automation Grade

- Automatic

- Usage & Applications

- Industrial Gas Production, Steel Plants, Refineries, Chemical Manufacturing

- Installation Guideline

- Site Preparation & Professional Installation Required

- Production Capacity

- 500 Nm3/hr

- Efficiency (%)

- Above 99%

- Motor Power

- 75 kW

- Driven Type

- Motor Driven

- Accessories

- Control Panel, Air Compressor, Expansion Turbine, Storage Tanks

- Type

- Liquid Air Separation Equipment

- Material

- Stainless Steel

- Computerized

- Yes

- Automatic Grade

- Fully Automatic

- Control System

- PLC Controlled

- Drive Type

- Electric

- Voltage

- 380-440 V

- Power

- 150 kW

- Weight (kg)

- 32000

- Dimension (L*W*H)

- 12m x 3m x 3.5m

- Color

- Blue / Silver

- Capacity

- 500 Cubic Meters per Hour

- Features

- High Purity Oxygen & Nitrogen Production, Low Power Consumption, Robust Construction, Low Maintenance

- Surface Finish

- Polished

- Machine Type

- Cryogenic Air Separation Plant

- Power Consumption

- 135-150 kW/Hr

- Shipping Condition

- Packaged in Custom Crates

- Input Air Pressure

- 6-8 Bar

- Compliance

- ISO 9001:2015 Certified

- Utilities Required

- Electricity, Cooling Water, Instrument Air

- Ambient Temperature Range

- 5°C to 45°C

- Cooling Method

- Cryogenic Refrigeration

- Oxygen Purity

- 99.7% (Typical)

- Spare Parts Availability

- Readily Available

- Service Life

- More than 20 Years

- Operation Safety

- Advanced Safety Systems Installed

- Noise Level

- Below 75 dB

- Operation Mode

- Continuous

- Documentation

- Operation & Maintenance Manual Supplied

- Flow Meter Type

- Digital Flow Meter

- Nitrogen Purity

- 99.9%

- Start-up Time

- 8-12 Hours

About 500 Cubic Meters Liquid Air Separation Equipment

500 m3 liquid equipment configuration list and power:

1. Centrifugal air compressor,model 7000 / 10, power 800 kW.

2. Precooler, model sayl-7000 / 10,produced in Hangzhou, with power of 40kW.

3. Purifier, model hxk-8000 / 10,power 140 kW (24 hours, actual use 6 hours).

4. Expander, 500y / 500.

5. Fractionator, model kd0n-180 /500y / 500, produced by Hangzhou foster company.

6. Instrument control, electriccontrol, buffer and other supporting devices of the whole equipment.

The installed power of the wholeset of equipment is 980 kW, and the normal production power is about 900 kW.

The purity of liquid oxygen is99.5%, and the output is about 0.65 tons of liquid oxygen per hour (convertedinto 500 cubic meters of oxygen).

High Purity Gas Production

The LAS500 air separation plant delivers oxygen purity of 99.7% and nitrogen purity of 99.9%, which meets the stringent requirements of demanding industrial applications. Its digital flowmeter and PLC-based control system ensure constant and precise monitoring of output, making it ideal for large-scale manufacturing and gas supply operations.

Robust and Reliable Construction

Constructed from premium-grade stainless steel, the LAS500 is designed for longevity and consistent operation under various ambient temperatures (5C to 45C). Its advanced safety systems and compliance with ISO 9001:2015 quality standards guarantee trouble-free operation and peace of mind for operators.

Efficient, Automated Operation

This equipment features fully automated, continuous-operation capability with a straightforward start-up process (8-12 hours). The requirement for minimal manual intervention ensures operational efficiency, while the auto-grade, PLC-controlled interface streamlines management and troubleshooting.

FAQ's of 500 Cubic Meters Liquid Air Separation Equipment:

Q: How does the LAS500 ensure high purity of oxygen and nitrogen?

A: The LAS500 uses advanced cryogenic separation processes and precise control systems. Its digital flowmeter and PLC controller continually monitor and adjust parameters, ensuring consistent production of oxygen at 99.7% purity and nitrogen at 99.9% purity.Q: What is the recommended installation process for this equipment?

A: Professional site preparation is vital. The equipment should be installed by qualified technicians in a well-ventilated, temperature-controlled area with access to electricity, cooling water, and instrument air. All units arrive packaged in custom crates to facilitate smooth delivery and setup.Q: When should routine maintenance be carried out, and are spare parts easy to obtain?

A: Routine maintenance should follow the guidelines provided in the Operation & Maintenance Manual. Spare parts are readily available from the manufacturer, ensuring minimal downtime and efficient servicing throughout the equipment's lifetime.Q: Where can the LAS500 be effectively utilized?

A: This equipment is suitable for deployment in industrial gas production facilities, steel plants, refineries, and chemical manufacturing units. Its robust design allows it to operate efficiently under varied ambient temperatures and demanding industrial environments.Q: What are the benefits of using a fully automatic, computerized air separation system?

A: A fully automatic, PLC-controlled system reduces manual labor, lowers the risk of human error, improves process efficiency, and allows for precise monitoring. This results in increased productivity, consistent gas purity, and enhanced safety during operation.Q: How energy-efficient is the LAS500 and what are its typical power requirements?

A: The LAS500 is designed for low power consumption, operating efficiently at 135-150 kW/hr. It runs on 380-440 V electricity, making it a cost-effective solution for large-scale production environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Air Separation Plant Category

10000 m3 Used Air Separation Equipment

Price 1000000000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Type : Used Air Separation Equipment

Automatic Grade : Automatic

Material : Stainless Steel

Computerized : Yes

3000 m3 Used Air Separation Equipment

Price 1000000000 USD ($) / Container

Minimum Order Quantity : 1 Unit

Type : Air Separation Equipment

Automatic Grade : Other, Fully Automatic

Material : Highgrade Steel

Computerized : Yes

6000 Cubic Meter Air Separation Plant

Minimum Order Quantity : 1 , , Plant

Type : Air Separation Plant

Automatic Grade : Automatic

Material : Highquality steel

Computerized : Yes

3000 Cubic Meter Air Separation Plant

Type : Air Separation Plant

Automatic Grade : Automatic

Material : Highgrade steel and specialized alloys

Computerized : Yes

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese