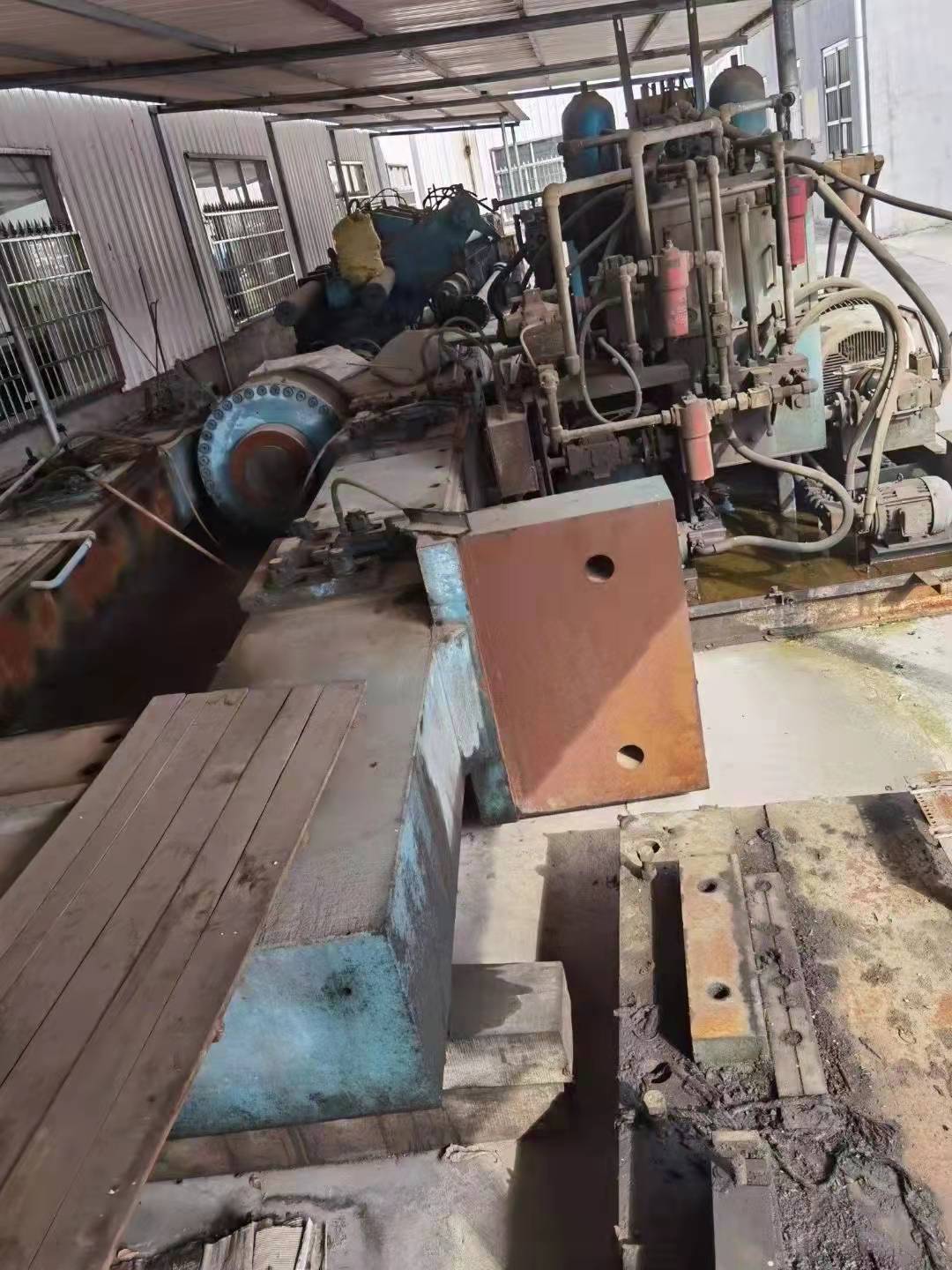

1450 Used Cold Rolling Mill

Price 1000000 USD ($)/ Unit

1450 Used Cold Rolling Mill Specification

- Type

- Used Cold Rolling Mill

- Material

- Mild Steel

- Capacity

- 20-25 Tons/Hour

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Control System

- PLC Based

- Voltage

- 380 - 415 V

- Power

- 300 Kw (Approx)

- Weight

- Approx 180 Tons

About 1450 Used Cold Rolling Mill

1450 cold rolling technical parameters

2.1 raw material specifications and technical requirements

Steel grade: 08Al, low carbon steel, SPHC, SPHD, sphe, SS400

Inlet thickness: 6mm

Entrance width: 900 1250mm

Maximum outer diameter: 1900mm

Inner diameter: 610mm/ 900mm

Maximum coil weight: 25t

Minimum inside diameter: 1000mm

Technical requirements: the surface quality, size, accuracy and chemical composition shall meet the "technical standard for hot rolled steel strip" (internal control) and corresponding GB requirements.

2.2 specifications and technical requirements of finished products

Finished product thickness: 0.25-2 mm

Finished product width: 900 1250mm

Maximum outer diameter: 1900mm

Nominal inside diameter: 510/ 1000- 1900mm

Maximum coil weight: 25t

Thickness tolerance: 0.3mm 10um; 3% when 0.30mm

Production capacity: 1.5 million tons / year

Advanced Four-High Reversible Design

With its 4 Hi reversible stand configuration, this used cold rolling mill offers enhanced strip flatness and superior thickness reduction. The five stands facilitate consistent processing, while reversibility allows bi-directional rolling, optimizing production efficiency for diverse steel coils. This flexibility enhances the mill's suitability for a range of industrial cold rolling requirements.

Efficient Cooling and Drive Mechanism

The integrated water spray cooling system ensures effective temperature control during operation, promoting high-quality surface finishes and extending roller lifespan. Advanced AC motor drive delivers reliable power and precision to accommodate demanding rolling speeds of up to 600 meters per minute, supporting the mill's substantial hourly capacity and production needs.

FAQ's of 1450 Used Cold Rolling Mill:

Q: How is the strip thickness adjusted during the cold rolling process?

A: Strip thickness is regulated by the 4 Hi reversible mill's hydraulic system and PLC-based controls, which enable precise settings for the roller gap during each pass. Operators can manually or semi-automatically select the desired thickness, ensuring output within the range of 0.2 mm to 2.5 mm.Q: What materials can be processed with the 1450 Used Cold Rolling Mill?

A: This mill is suitable for mild steel coils, allowing efficient reduction of input sheet thicknesses up to 4 mm into rolled strips of 0.2-2.5 mm thickness. Its robust design ensures consistent processing and surface quality for steel coil applications.Q: Where can this rolling mill be installed and operated?

A: The mill is designed for installation in steel processing facilities, manufacturing plants, or coil service centers. Its versatility and moderate space requirements (42 meters line length) make it a practical choice for various industrial settings, particularly those focused on cold rolling operations.Q: What are the operational benefits of the water spray cooling system?

A: The water spray cooling system efficiently removes heat generated during high-speed rolling. This maintains optimal roller and strip temperatures, resulting in improved surface finish, reduced risk of thermal damage, and enhanced mill component longevity.Q: When was this cold rolling mill manufactured and what is its current condition?

A: The 1450 Used Cold Rolling Mill was manufactured in 2005 in China and is currently in good used condition, ready for export, supply, or trade.Q: What is the maximum production capacity of the mill?

A: The mill can process 20-25 tons of steel coils per hour, depending on material quality, strip width, and operational parameters.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rolling Mill Machine Category

650 Strip Mill

Price 1000000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

Automatic Grade : Automatic

Voltage : 220440 V

Material : Mild Steel

1450 Hot Roll Mill

Price 10000000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

Automatic Grade : Automatic

Voltage : 380V / 415V

Material : Mild Steel

Used Wire Mill

Price 1000000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Automatic Grade : SemiAutomatic

Voltage : 415 V

Material : Mild Steel

950 Steel Rolling Plant

Price 10000000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

Automatic Grade : Automatic

Voltage : 380440 V

Material : Mild Steel

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese