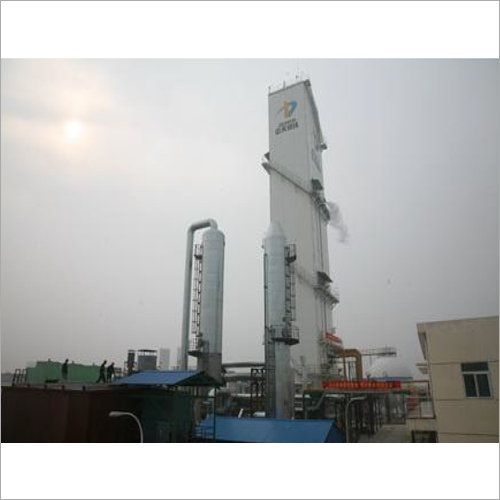

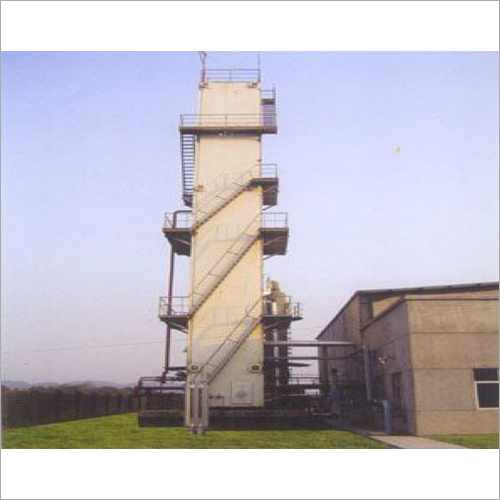

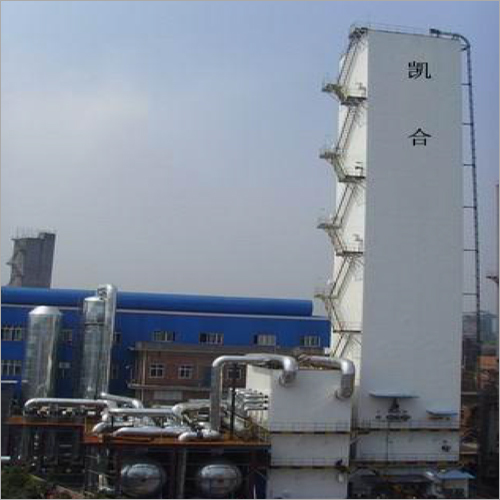

3000 m3 Used Air Separation Equipment

Price 1000000000 USD ($)/ Container

MOQ : 1 Unit

3000 m3 Used Air Separation Equipment Specification

- Usage & Applications

- Industrial Gas Production, Steel Plants, Chemical Processing, Medical Facilities

- Efficiency (%)

- 95%

- Accessories

- Purification Skids, Control Panels, Storage Tanks

- Model No

- ASU-3000

- Temperature Range

- -180C to +50C

- Frequency

- 50 Hz

- Driven Type

- Electric Motor

- Speed

- Variable

- Automation Grade

- Automatic

- Installation Guideline

- On-site Commissioning Available

- Motor Power

- 750 kW

- Production Capacity

- 3000 Nm/h Oxygen; 3000 Nm/h Nitrogen

- Type

- Air Separation Equipment

- Material

- High-grade Steel

- Computerized

- Yes

- Automatic Grade

- Fully Automatic

- Control System

- PLC Based

- Drive Type

- Electric

- Voltage

- 380 V / 415 V

- Power

- 750 kW

- Weight (kg)

- 75000 kg (Approx.)

- Dimension (L*W*H)

- Custom (Site Dependent)

- Color

- Grey

- Capacity

- 3000 m3/h

- Features

- Energy Efficient, High Purity Output, Low Maintenance, Robust Design

- Machine Type

- Cryogenic Type Separation Unit

- Power Consumption

- Approx. 750 kW

- Surface Finish

- Anti-corrosive Painted

- Noise Level

- 85 dB(A)

- Purity Level Oxygen

- 99.6%

- Purity Level Nitrogen

- 99.99%

- Cooling Method

- Cryogenic

- Dismantling Status

- Ready for Transit

- Operational Hours

- Less than 16,000 hours

- Plant Condition

- Used, Well-Maintained

- Product Gases

- Oxygen, Nitrogen, Argon

- Service Support

- Not included

- Refrigerant Used

- None (cryogenic process)

- Operating Pressure

- Up to 6 bar

- Plant Year of Manufacture

- 2017

- Relocation Possibility

- Yes, complete relocation possible

About 3000 m3 Used Air Separation Equipment

Main indicators

| productWorking condition ICondition II

liquid oxygenLiu og3000 Nm3/ h2000 Nm3/ hpressure0. 8MPa0. 8MPapurity99. 5% 0299. 5% 02 liquid nitrogenflow0 Nm3/ h1100 Nm3/ hpressure | 0.35 MPapurity10 ppm 02;1 0 ppm 02 | |

| Equipment list of 3000 liquefaction unit | |||||

| Serial number | Device description | Equipment classification | Specification, model and main parameters | quantity | Manufacturer |

| 1 | 3000 external device - liquefaction main tower | Pagoda | 3000m/h | 1 set | Henan Kaiyuan Air Separation Group Equipment Co., Ltd |

| 2 | 3000 external device - high and low temperature expansion oil station | pump | Model: gy-80 * 2 / 10, oil supply flow: 80 * 2L / min, oil supply temperature: 43 , oil supply pressure: < 1.0MPa. | 1 set | Sichuan Jianyang Ruite mechanical equipment Co., Ltd |

| 3 | 3000 external device - liquid oxygen into storage tank liquid oxygen pump | pump | Model: ac30fc, component: 56895-100ablc, rotating speed: 2950rpm, pump size: 1 * 2 * 4.5 inches, material;Bronze, hydraulic test: 155psig, motor power: 5te | 1 set | American ACD |

| 4 | 3000 external device - high temperature expander | Refrigeration equipment | Working medium flow of nitrogen expander: pk-74.00m, pk-24.00m/h. Booster flow: 15600m/h. Expander inlet pressure: 2.575mpa, booster inlet pressure: 2.585mpa, expander outlet pressure: 0.474mpa, booster outlet pressure: 3.68mpa, expander inlet temperature: - 26 , booster inlet temperature: 40 , speed: 43210r / min. | 1 set | Sichuan Jianyang Ruite mechanical equipment Co., Ltd |

| 5 | 3000 external device - low temperature expander | Refrigeration equipment | Model: plpk-195.77/45.3-3.83, working medium: nitrogen, expander flow: 11746m/h. Booster flow: 15600m/h. Expander inlet pressure: 4.63mpa, booster inlet pressure: 3.665mpa, expander outlet pressure: 0.483mpa, booster outlet pressure: 4.67mpa, expander inlet temperature: - 109 , booster inlet temperature: 40 , speed: 45170r / min. | 1 set | Sichuan Jianyang Ruite mechanical equipment Co., Ltd |

| 6 | 3000 external device - circulating nitrogen compressor | compressor | Model: 3tvc44, medium: nitrogen, flow: 26500nm/h. Inlet pressure: 343kpa, exhaust pressure: 2.6MPa, inlet temperature: 40 , working speed of each shaft: 2983 / 23381 / 24889r / min, driving power: 2800KW. | 1 set | Hangzhou Hangyang Turbine Machinery Co., Ltd |

| 7 | 3000 external device - raw material nitrogen compressor | compressor | Model: lgw425 / 0227, nominal volume flow: 88m/Min, rated exhaust pressure: 0.35Mpa, driving power: 425kw, driving speed: 1480r / min. | 1 set | Wuxi Compressor Co., Ltd |

| 8 | 3000 external device - buffer tank | pot | Product No.: f12106, volume: 10MDesign pressure: 0.09mpa, design temperature: 20 , working medium: oxygen and nitrogen. | 1 set | Henan Kaiyuan Air Separation Group Equipment Co., Ltd |

| 9 | 3000 external device - expander aftercooler | Heat exchanger | Product No.: h120603101, volume: 10MDesign pressure: 0.8MPa, design temperature: 120 , working medium: compressed nitrogen, heat exchange area: 220.7m2, main material: s30408 / 1060. | 2 sets | Hubei Difeng heat exchanger Co., Ltd |

| 10 | 3000 external device - trace water analyzer | Analyzer | Model: ta2000-dp, range: - 80 - + 20 | 2 sets | Chongqing Trier |

Reliable High-Purity Gas Production

Deliver premium-quality oxygen, nitrogen, and argon with exceptional purity using our cryogenic air separation plant. Designed for continuous operation and robust performance, this equipment leverages advanced automation and a high-efficiency cryogenic process for cost-effective, energy-efficient gas output.

Engineered for Longevity and Adaptability

Manufactured in 2017 and maintained in excellent condition, the plant features durable high-grade steel construction with an anti-corrosive surface finish. Customizable for site-specific dimensions and ready for complete relocation, it suits diverse environments and industrial requirements.

Comprehensive Features and Accessories

This air separation unit comes fully automated with PLC controls, purification skids, and storage tanks. It maintains a low noise level (85 dB(A)) and offers easy installation with available on-site commissioning. The built-in energy-saving design further reduces operational costs.

FAQs of 3000 m3 Used Air Separation Equipment:

Q: How does the cryogenic process of this air separation unit work?

A: The cryogenic process involves cooling air to extremely low temperatures, separating its components (oxygen, nitrogen, argon) through fractional distillation. The entire process is fully automated and controlled via a PLC system, ensuring precise and efficient gas production.Q: What are the key benefits of using this used air separation equipment?

A: You gain high-purity oxygen (99.6%) and nitrogen (99.99%), robust reliability, low maintenance, and energy efficiency (95%). The system is ready for immediate relocation, delivering cost savings and a shorter lead time compared to new equipment.Q: Where can this air separation plant be used?

A: This equipment is ideal for a range of applications, including steel manufacturing, chemical processing plants, industrial gas suppliers, and medical facilities requiring steady, high-quality gas output.Q: What is included with the equipment upon purchase?

A: The plant includes purification skids, control panels, storage tanks, and all main systems fully assembled. The unit is ready for transit, with on-site commissioning offered for streamlined installation at your facility.Q: When was the air separation plant manufactured and how many hours has it operated?

A: The plant was manufactured in 2017 and has operated for less than 16,000 hours, ensuring a long remaining service life and reliable performance for future users.Q: How difficult is it to relocate and install this air separation unit?

A: Relocation is straightforward the unit is ready for transit, and complete site installation is possible with guidance or on-site commissioning. Custom dimensions and comprehensive modular accessories allow for flexible adaptation to new environments.Q: What levels of purity and production can I expect from this plant?

A: You can expect oxygen purity of up to 99.6% and nitrogen purity up to 99.99%, each at a production rate of 3000 Nm/h. Consistent, high-purity outputs are ensured by advanced controls and the intrinsic strengths of the cryogenic method.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Air Separation Plant Category

500 Cubic Meters Liquid Air Separation Equipment

Minimum Order Quantity : 1 Unit

Automatic Grade : Other, Fully Automatic

Material : Stainless Steel

Drive Type : Electric

Voltage : 380440 V

350 Cubic Meter Air Separation Plant

Automatic Grade : Automatic

Material : Stainless Steel

Drive Type : Electric

Voltage : 400V

2000 Cubic Meter Air Separation Plant

Automatic Grade : Automatic

Material : Stainless Steel

Drive Type : Electric

Voltage : 380415 V

3000 Cubic Meter Air Separation Plant

Automatic Grade : Automatic

Material : Highgrade steel and specialized alloys

Drive Type : Electric

Voltage : 220440V

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese