6300KVA Submerged Arc Furnace

Price 10000000 USD ($)/ Unit

6300KVA Submerged Arc Furnace Specification

- Feature

- Heavy Duty, High Thermal Efficiency, Modular Design

- Rating

- 6300 KVA

- Condition

- New

- Type

- Submerged Arc Furnace

- Usage

- Industrial Melting

- Power

- 6300 KVA

- Voltage

- 33000 V (input voltage)

- Size

- Customizable based on site requirements

- Dimensions

- Variable; depends on capacity

- Weight

- Approx. 200-400 tons (depends on configuration)

- Application

- Ferroalloy, Silicon, Calcium Carbide, Metal Extraction

- Fuel Type

- Electric

- Capacity

- 25000-40000 tons/year (approx)

- Transformer Cooling

- Oil Cooled/Water Cooled

- Electrode Diameter

- 350-800 mm (as per design)

- Electrode Type

- Self-Baking or Pre-baked Carbon Electrodes

- Electrode Lifting System

- Hydraulic/Electromechanical

- Refractory Lining

- High Aluminia/Basic Lining

- Operation Mode

- Continuous/Batch

- Tap to Tap Time

- Variable based on charge and process

- Shell Material

- Steel plate with water/air cooling facilities

- Cooling System

- Water/Air Cooling Jacket

- Control System

- Automatic/PLC Based Controls

- Compliance

- ISO/IEC Standards

- Max Operating Temperature

- Up to 2500°C

- Current Type

- AC (Alternating Current)

- Phase

- Three Phase

- Fume Extraction

- Integrated dust and fume collection system

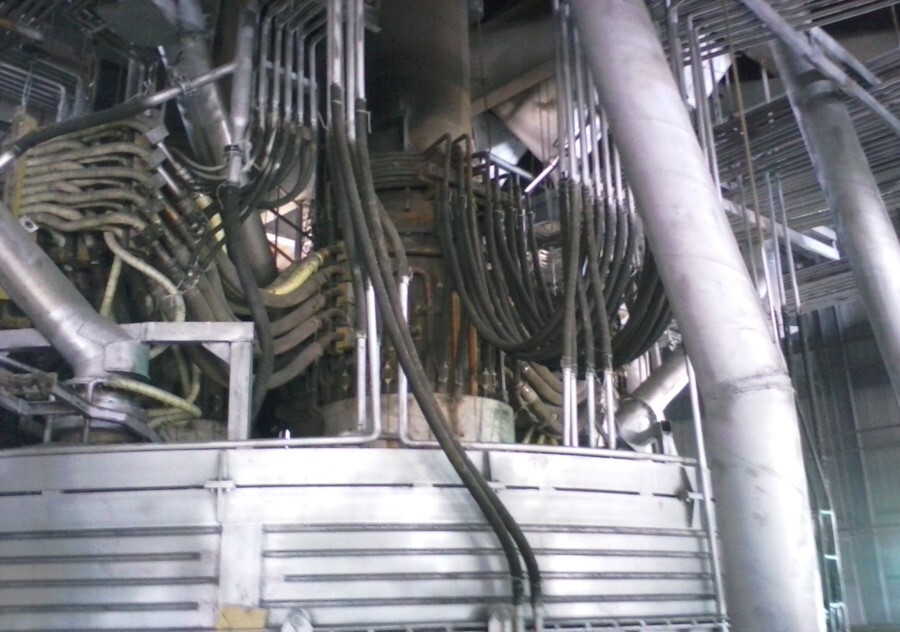

About 6300KVA Submerged Arc Furnace

Technical parameters:

Transformer capacity: 6300KVA

Primary side voltage: 11kv

Secondary side voltage: 98 106 126 (V)

Secondary side voltage level: 8, level difference: 4V

Common voltage: 106 (V)

Electrode diameter: 800mm

Diameter of electrode center circle: 2100mm

Furnace diameter: 5000

Furnace depth: 2000mm

Shell diameter: 6700mm

Furnace shell height: 3800mm

Height of low smoke hood: 1800 mm

Electrode stroke: 1500 mm

Electrode lifting speed: 0.5m/min

Cooling water consumption: 280t / h

Advanced Cooling for Optimal Performance

The furnace shell is constructed with high-grade steel plate and equipped with water or air cooling jackets, ensuring optimal thermal regulation during high-temperature operations. Transformer cooling is available in both oil and water-cooled systems. This sophisticated cooling infrastructure extends furnace life, maintains safe operating conditions, and supports continuous high-efficiency performance, even under demanding melting cycles.

Integrated Fume Extraction and Environmental Compliance

A dedicated dust and fume collection system is integrated within the furnace, capturing harmful emissions directly at the source. This not only facilitates a cleaner work environment but also ensures compliance with stringent environmental and industrial safety standards, supporting sustainable operations for modern manufacturing facilities.

Customizable Design for Industrial Applications

With flexible electrode sizes, configurable refractory lining, and modular construction, this furnace is adaptable for various site requirements. Whether melting ferroalloys, silicon, calcium carbide, or extracting metals, each unit can be engineered to match specific operational needs, production capacity, and space constraints. This ensures seamless integration into diverse industrial contexts, maximizing productivity.

FAQ's of 6300KVA Submerged Arc Furnace:

Q: How does the 6300KVA Submerged Arc Furnace achieve high thermal efficiency during industrial melting?

A: The furnace utilizes advanced water or air cooling systems for both the shell and transformer, along with precise PLC-based controls to optimize energy usage and heat distribution. The use of high aluminia or basic refractory lining retains heat effectively, ensuring minimal energy loss and consistent performance at elevated temperatures.Q: What types of electrodes can be used, and how are they selected for different melting processes?

A: This furnace accommodates both self-baking and pre-baked carbon electrodes, with diameters ranging from 350 to 800 mm as required by design. Electrode type and size are chosen based on the raw materials, desired product, and process characteristics to ensure effective current transfer and melting.Q: When is the fume extraction system activated, and what benefits does it provide?

A: The integrated fume extraction system operates simultaneously with furnace melting activities, capturing dust and fumes produced during operation. This action promotes a healthier work environment, reduces environmental impact, and supports adherence to ISO/IEC standards for industrial air quality and safety.Q: Where can the 6300KVA Submerged Arc Furnace be installed, and is it customizable for specific sites?

A: The furnace's modular design and customizable dimensions allow installation in various industrial settings, including factories for ferroalloy, silicon, calcium carbide, and metal extraction. Each unit is tailored to individual site requirements for capacity, space, and process demands.Q: What is the typical process for controlling operation and monitoring performance?

A: Operations are controlled automatically through PLC-based systems, providing real-time monitoring and adjustments for temperature, electrode position, and melting parameters. This automation ensures consistency, safety, and optimal output throughout both continuous and batch operational modes.Q: How is the electrode lifting system configured, and what are its advantages?

A: The furnace employs a hydraulic or electromechanical lifting system to adjust electrode positions precisely. This offers smooth operation, minimal downtime, and enhanced control over the melting process, catering to different electrode sizes and process requirements.Q: What are the primary benefits of using this type of furnace for industrial metal extraction?

A: Customers benefit from high production capacity, heavy-duty design, efficient energy utilization, and the ability to operate at temperatures up to 2500C. The integrated solutions for cooling, fume extraction, and automated control provide reliability, safety, and environmental compliance, underpinning efficient large-scale industrial operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Electric Arc Furnace Category

Used 20T Electric Arc Furnace

Price 10000000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Feature : Rapid Melting, Automated Controls, High Temperature Performance

Voltage : 380440 V (operating)

Usage : Other, Steel Melting / Metallurgical Industry

Size : 20 Ton

Used 10T Electric Arc Furnace

Minimum Order Quantity : 1 Container

Feature : High Melting Efficiency, Robust Construction

Voltage : 380440V

Usage : Other, Steel Melting

Size : 10 Tons

30 Ton Electric Arc Furnace

Feature : High efficiency energysaving operation

Voltage : Variable depends on configuration

Usage : Other, Metal melting and refining

Size : Large industrial scale

25 Ton Electric Arc Furnace

Feature : High efficiency advanced control system

Voltage : Highvoltage operation

Usage : Melting scrap or raw materials for steel production, Other

Size : Medium to large industrial scale

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese