Used 10T Electric Arc Furnace

Used 10T Electric Arc Furnace Specification

- Feature

- High Melting Efficiency, Robust Construction

- Rating

- Industrial Grade

- Condition

- Used

- Type

- Electric Arc Furnace

- Usage

- Steel Melting

- Power

- 3-Phase Electric

- Voltage

- 380-440V

- Size

- 10 Tons

- Dimensions

- Customized/As per manufacturer specs

- Weight

- Approx. 60-75 Tons

- Application

- Metallurgical Industry, Steel Plants

- Fuel Type

- Electricity

- Capacity

- 10 Ton per batch

About Used 10T Electric Arc Furnace

Equipment parameters of 10t electric arc furnace

Rated capacity: 10 tons

Maximum capacity: 14 tons

Transformer capacity: 5500kva

Electrode diameter: 350mm

Furnace shell diameter: 3600mm

Production date: April 2017

Efficient Steel Melting

With a capacity of 10 tons per batch and a melting cycle time of just 4560 minutes, this electric arc furnace delivers exceptional throughput for steel manufacturers. Its high transformer capacity, robust design, and advanced control system optimize melting performance while maintaining safety.

Durable, Industrial-Grade Construction

Constructed with a heavy duty steel shell, this arc furnace is engineered for longevity and demanding industrial use. The built-in refractory lining and water cooling system ensure the furnace remains structurally sound and efficient throughout continuous operation.

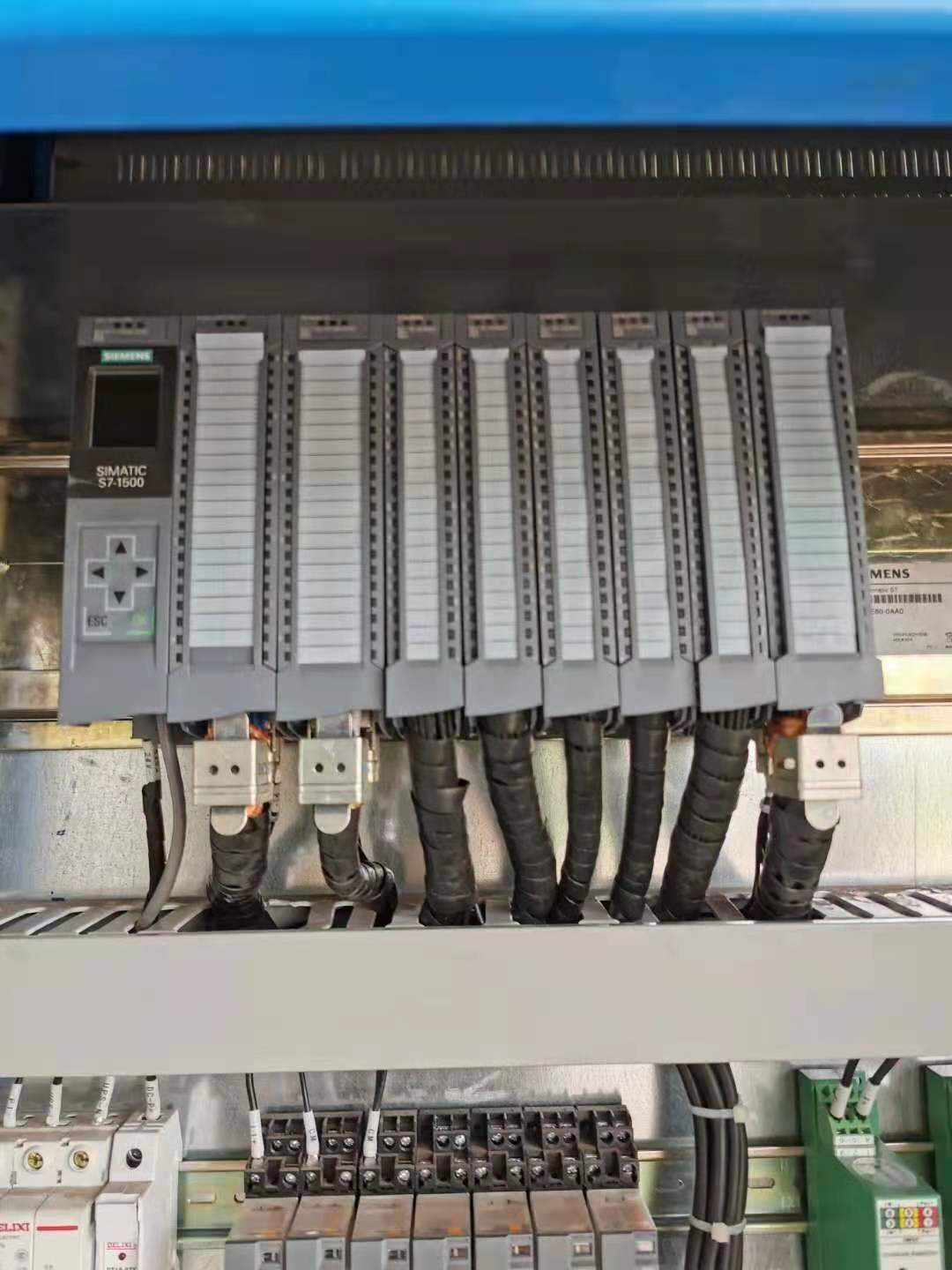

Comprehensive Safety and Control

The included PLC/manual control system provides flexible operation, while integrated safety alarms and water cooling protect both operators and equipment. The eccentric bottom tapping (EBT) method also enhances safety and efficiency during the molten steel pouring process.

FAQs of Used 10T Electric Arc Furnace:

Q: How is the 10T Electric Arc Furnace installed and what infrastructure is required?

A: Installation requires a proper foundation and EAF-compatible power infrastructure. It operates on 3-phase electricity at 380440V, so ensure your facility meets the electrical and structural requirements before setup.Q: What are the main operational benefits of using this furnace for steel melting?

A: This furnace offers high melting efficiency, robust construction, and a quick melting cycle (4560 minutes per batch). Its industrial-grade materials and control systems provide increased safety, durability, and operational reliability for metallurgical applications.Q: When should the refractory lining be inspected or replaced?

A: Although the refractory lining is installed, it is recommended to inspect it before commissioning and regularly during operation. The replacement frequency depends on usage intensity and the types of materials processed.Q: Where is eccentric bottom tapping (EBT) used in this furnace, and why?

A: The EBT system is used during molten steel discharge to minimize slag in the tapped metal and enhance worker safety. This tapping method is located at the lower eccentric part of the furnace shell.Q: What is included with the used furnace in terms of spare parts and accessories?

A: A basic set of spare parts is included in as-is condition. Additional spares or specific components should be sourced separately as needed for ongoing maintenance.Q: How is safety ensured during furnace operation?

A: Safety is supported by a combination of PLC/manual controls, comprehensive alarm systems, and a water cooling system that mitigates overheating risks, protecting both operators and equipment.Q: What types of steelmaking applications is this furnace suitable for?

A: It is ideally suited for industrial-scale steel production in metallurgical industries and steel plants, delivering consistent, high-quality melted steel suitable for various downstream processes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Electric Arc Furnace Category

6300KVA Submerged Arc Furnace

Price 10000000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Feature : Heavy Duty, High Thermal Efficiency, Modular Design

Application : Ferroalloy, Silicon, Calcium Carbide, Metal Extraction

Size : Customizable based on site requirements

Voltage : 33000 V (input voltage)

Brown Corundum Smelting Furnace

Price 1000000000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Feature : High melting efficiency, energysaving, robust design, automated controls

Application : Abrasive manufacturing, refractory materials, industrial smelting

Size : Customizable as per requirement

Voltage : 380 V / 415 V (as required)

20 Ton Electric Arc Furnace

Minimum Order Quantity : 1 , , Unit

Feature : Efficient energy conversion and precise temperature control

Application : Industrial Steelmaking

Size : Large

Voltage : High Voltage industrialgrade Volt (v)

5 Ton Electric Arc Furnace

Feature : Efficient smelting and high temperature control

Application : Steelmaking

Size : Largescale

Voltage : High voltage operation

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese